Metals like aluminum, zinc, and magnesium, benefit most from chromate conversion finishing and why each requires a tailored process for lasting protection.

Aluminium Alloys

Aluminium is the most common substrate for chromate conversion coating, especially in aerospace, electronics and general manufacturing. The process enhances corrosion resistance of lightweight aluminium parts without significant dimensional change, crucial for precision assemblies.

Zinc, Magnesium, and Other Alloys

Beyond aluminium, chromate conversion treatments are used on zinc or zinc-plated steel (especially fasteners), magnesium alloys, cadmium-plated parts, copper, tin, silver alloys, and other specialty substrates. For example, zinc plating followed by chromate conversion enhances the zinc’s corrosion-protection performance.

Pretreatment for Other Finishes

Chromate conversion is often used as a pretreatment before painting, powder coating or adhesive bonding. The coating acts as a primer layer, improving the adhesion of subsequent coatings and preserving the underlying metal from corrosion.

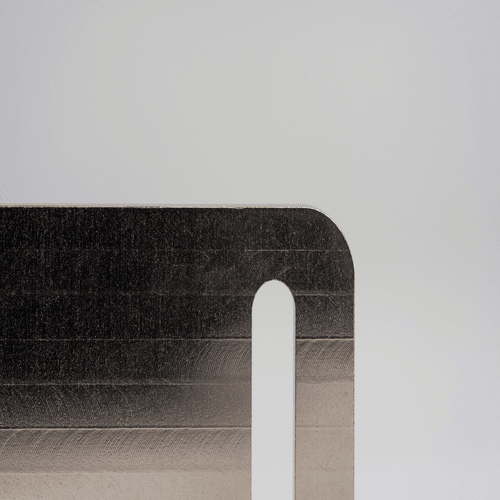

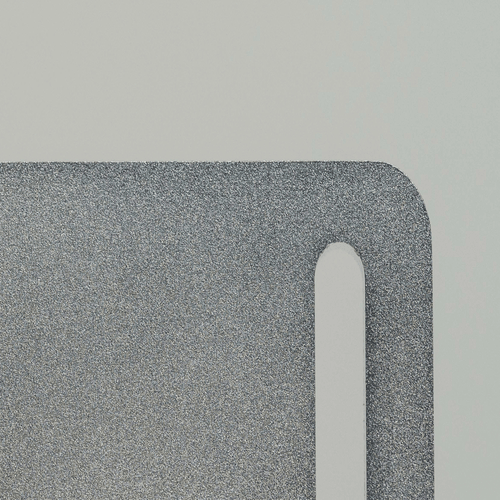

Precision Machined Parts Requiring Finishing

For a machining house like XC Machining, where machined parts may have tight tolerances, finely machined surfaces and may require finishing for functional coatings, offering chromate conversion finishing means you can provide a full solution: from CNC machining to surface treatment to delivery.