CNC machining is a flexible process in manufacturing and it involves the production of components whose shapes and size are repeatable and accurate under the assistance of computer-controlled tools. The types of CNC machines are different in that they are used in the accomplishment of a different purpose thus specific abilities are presented.

The major types of CNC machines and their functionality with their common uses have been described below.

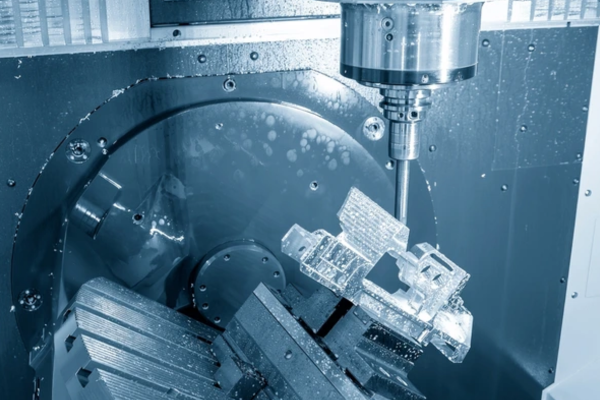

CNC Milling Machines

The most versatile and the most common of CNC processes is CNC milling. Such machines have rotating multi-point cutting tools which are deployed to cut out a workpiece.

Configuration of Axes: In general, they are 3 axes, yet 4, 5, or 6 axes can offer far more adaptability.

Normal Operations: These are Face mill, contour, slot, drilling and tapping.

Applications: Material used to make after market automotive, aerospace, and consumer electronic components where precise shapes, and tight tolerances are needed.

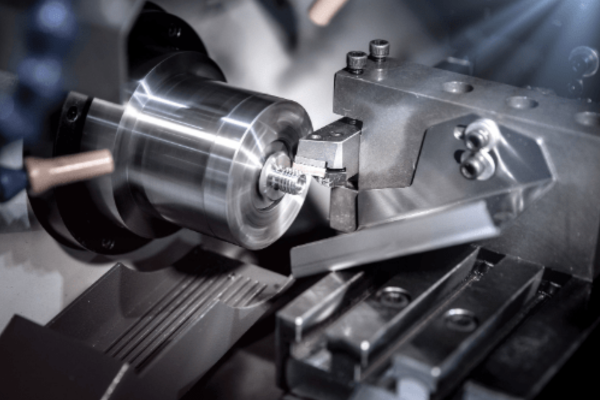

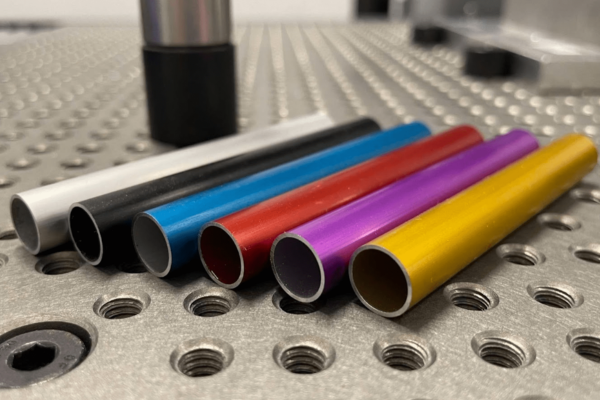

CNC Lathes, and Turning Machinery

The machine tools that are suitable in the production of cylindrical/ round shapes are the CNC lathes. The substance of the work (workpiece) is turned whereas a fixed instrument is used in shaping the workpiece.

Abilities: Sanding, facing, knurling, drilling, threading and cutting.

Advantages: Great precision in case of symmetrical form and supreme surface finishes.

Applications: Shafts, bushings, pulleys and others that rotate.

CNC Routers

CNC routers are similar to the milling machines although in most cases they run on softer materials.

- Materials: Wood, plastic, foam and composite panels.

- Capacities: 2D and 3D carving, engraving and shaping.

- Uses: Furniture, sign, architectural models and decorative parts.

CNC Plasma cutters

Plasma CNC machines are utilized in an electrically conductive gas (plasma) which is used in cutting through the metal in the most precise way possible.

Speed and Efficiency: Able to cut thick metal sheets quite fast.

Applications: Body parts of cars, metal works, and steel structures.

CNC Laser Cutting Machines

Laser cutters involve beams of light focussing in the place of melting or burning and evaporating material.

Advantages: Can be very accurate and waste very little material and has clean edges.

Material: Metals, plastics, wood and ceramics.

Application: Checking housings, electronic applications and sign boards.

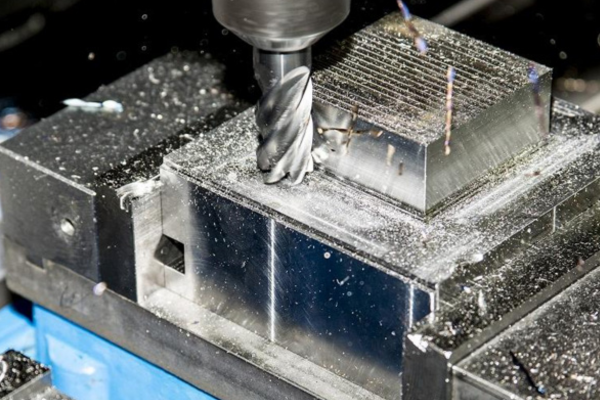

CNC Drilling Machines

CNC drilling machines are those machines that make holes or drill holes. It is specialized in drilling holes with high levels of accuracy and repeatability.

- Types of Drilling: Spot drilling, peck drilling, and deep hole drilling.

- Applications: Circuit boards, automotive components, aerospace components.

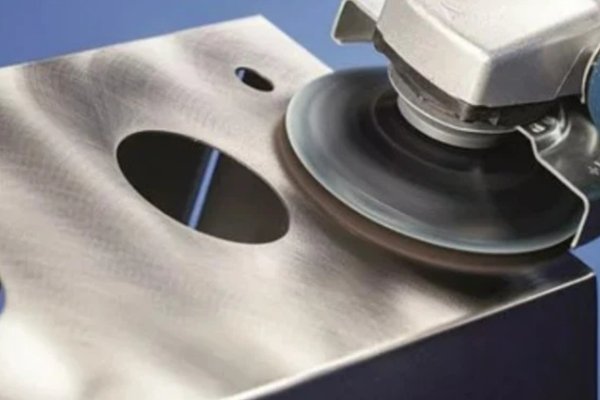

CNC Grinders

The abrasive wheels are used in the machines to attain very thin surfaces.

Abilities: Surface Grinding and Cylindrical Grinding and tool sharpening.

Applications: Precision mold parts, bearing surfaces or cutting tools.

CNC Water Jet Cutting Machines

The water jets are cutting tools delivered in the form of high pressure water with or without abrasive particles.

Advantages: There are no heat-affected areas, so this is suitable in cases of temperature-sensitive materials.

Application: Stone work surfaces, panels and windows, aircraft materials.

Electrical Discharge Machining (EDM)

EDM removes material by means of regulated electrical sparks in a dielectric bush.

Types of EDM: sinkerEDM and Wire EDM.

Advantages: Able to make machines very hard, or complex shaped materials.

Applications: Injection molds, turbine blade and medical implants.

3D CNC Machines / Additive Hybrid CNC

Hybrid machines are an additive combination with CNC subtractive machining.

Advantages: The building is done layer-by-layer of complex shapes and lastly, the machining is done and calibrated accurately.

Applications: Prototyping, Aerospace components, custom tooling.

Multitasking (Turn-Mill) Machines

Multitasking machines incorporate the features of both milling and turning all in one machine.

Advantages: It eliminates the use of several machines which increases efficiency.

Applications: Complicated components that deal with rotational and the milled geometries.

5-Axis CNC Machines

In 5-axis machining, movement of the cutting tool or in some cases the workpiece may occur in five axes at the same time.

Advantages: It can machine complex geometry in fewer set ups, and more accurately.

Applications: A freshwater reactor component, medical implant, mold tool.

What Technologies are Used in CNC Machining?

CNC machining is based on various superior technologies, which interact to guarantee accuracy, effectiveness, and a standard of merit as far as manufacturing is concerned.

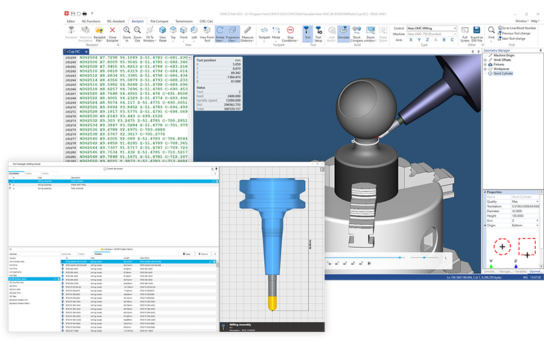

CAD/CAM Integration

CAD and CAM software have collaboration where they help in designing parts and calculating accurate toolpaths. This integration means that more of the designs get accurately translated into machining instructions, lessening the error and quickening the production.

G-Code Programming

The standard language across the CNC machines is G- Code; it governs movements, speeds and tool changes. The result of the modern CNC arrangements utilizes the CAM software, so it automatically creates G-Code, thus making programming more accurate and swift.

Automatic Tool Changers (ATC)

The use of ATCs enables the CNC to change cutting tools and operate using different ones without the involvement of a human operator. This saves on down time, makes them more efficient and can machine complex parts in one set up.

Multi-Axis Machining

In addition motions in 3 axes, high-quality CNC machines may work on 4, 5-axes, and further. Multi-axis machining allows the manufacturing of complex shapes at fewer set ups and with increased accuracy (in case of aerospace and medical machining).

IoT and Smart Monitoring

In modern CNC machines, there is the presence of sensors with which the CNC machines are connected to the Industrial Internet of Things (IIoT). With this technology, they can monitor it in real-time, predict the maintenance as well as do data-driven engineering to achieve maximum productivity.

Ready to Bring Your Precision Parts to Life?

At XC Machining, we combine advanced CNC technologies with expert craftsmanship to deliver high-quality components for industries worldwide. Whether you need prototypes, small batches, or large-scale production, our team ensures accuracy, efficiency, and reliability in every project.

Contact us today to discuss your requirements and get a fast, competitive quote!