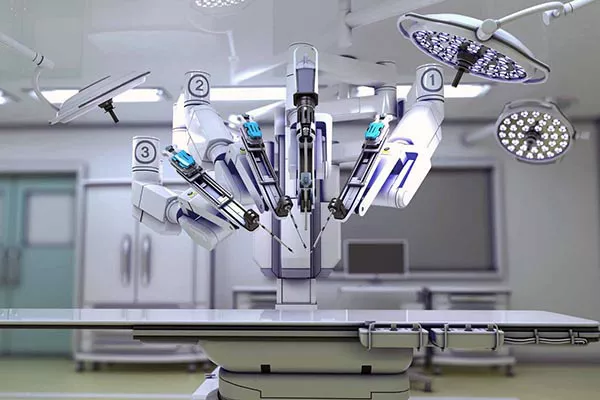

Precision defines the medical device industry. When a surgeon relies on an instrument during a delicate procedure, when a diagnostic device analyzes critical biomarkers, or when an implantable component integrates with human tissue, the dimensional accuracy of every component becomes paramount. Medical CNC machining has emerged as the manufacturing method of choice for producing these precision components, but exactly how accurate can this technology be? Understanding the achievable accuracy levels, the factors influencing precision, and the verification methods used in medical CNC helps manufacturers, engineers, and procurement professionals make informed decisions about component specifications, supplier selection, and quality assurance protocols that ultimately impact patient safety and device performance.

Table of Contents

Understanding Accuracy in Medical CNC Machining

Before exploring specific tolerance capabilities, it’s important to distinguish between accuracy, precision, and repeatability in the context of CNC machining for medical industry applications. Accuracy refers to how closely a machined dimension matches the intended specification. Precision indicates the consistency of repeated measurements or operations. Repeatability describes the ability to produce identical results across multiple parts or production runs.

Medical device CNC machining must excel in all three areas. A surgical instrument component measuring 10.000mm when the specification calls for 10.000mm demonstrates accuracy. If one hundred identical parts all measure between 9.998mm and 10.002mm, the process demonstrates precision. When parts produced months apart exhibit the same dimensional consistency, the process proves its repeatability.

Modern medical CNC equipment routinely achieves tolerances that would have been considered impossible just decades ago, with standard capabilities reaching ±0.0005″ (±0.013mm) and specialized operations achieving even tighter specifications under controlled conditions.

Standard Tolerance Capabilities in Medical CNC

Most medical CNC machining operations work within tolerance ranges that balance achievable accuracy with economic practicality. Understanding these standard capabilities helps set realistic specifications.

Factors Affecting Medical CNC Accuracy

Numerous variables influence the achievable accuracy in CNC machining medical devices. Understanding these factors helps manufacturers optimize processes and helps designers specify realistic tolerances.

Machine Quality and Condition

The foundation of precision medical CNC machining starts with equipment quality. Industrial-grade CNC machines designed for medical applications feature:

Rigid construction: Heavy cast iron or granite beds minimize vibration and deflection during cutting operations. Machine rigidity directly correlates with achievable accuracy—flexible machines cannot maintain tight tolerances under cutting forces.

Precision linear guides: High-quality ball screws, linear motors, or hydrostatic bearings provide positioning accuracy measured in microns. Medical CNC equipment typically features ground ball screws with tolerances of C3 or C5 grades (3-5 microns per 300mm).

Thermal stability: Temperature fluctuations cause metal expansion and contraction affecting dimensional accuracy. Advanced medical CNC systems incorporate thermal compensation software that adjusts for temperature-related dimensional changes in real-time.

Spindle precision: High-speed spindles in medical device CNC machining must maintain minimal runout—typically under 0.0001″ (0.0025mm) TIR (Total Indicator Reading). Even microscopic spindle runout translates directly into part dimensional errors.

Machine age and maintenance history significantly impact accuracy. Well-maintained 10-year-old machines from quality manufacturers often outperform poorly maintained new equipment. Regular calibration, worn component replacement, and preventive maintenance preserve accuracy throughout machine service life.

Material Properties and Behavior

Different materials used in CNC machining for medical industry applications exhibit varying machinability and stability characteristics affecting achievable accuracy.

Thermal expansion coefficients: Materials expand and contract with temperature changes during machining. Aluminum expands approximately twice as much as stainless steel for equivalent temperature changes. Medical CNC operations must account for thermal effects through cooling periods, temperature-controlled environments, or compensation algorithms.

Elastic modulus and deflection: Softer materials like plastics deflect under cutting forces more than metals, making tight tolerances more challenging. Thin-walled components in any material present deflection challenges requiring specialized fixturing and cutting strategies.

Internal stresses: Bar stock and forgings contain residual stresses from manufacturing. Machining removes material, releasing these stresses and causing dimensional changes. Stress-relieved materials provide better dimensional stability for precision medical CNC turning operations.

Material homogeneity: Consistent material properties throughout workpieces enable predictable machining behavior. Variations in hardness, grain structure, or composition cause tool wear patterns and cutting force variations affecting dimensional consistency.

Common medical device materials and their machinability considerations:

Stainless steel (316L, 17-4PH): Excellent for implantables and surgical instruments. Work-hardens during cutting requiring sharp tools and appropriate cutting parameters. Standard tolerances of ±0.001″ readily achievable.

Titanium alloys (Ti-6Al-4V): Superior biocompatibility for implants. Low thermal conductivity causes heat buildup at cutting edge. Specialized tooling and cutting fluids enable ±0.0005″ tolerances with proper techniques.

Medical-grade plastics (PEEK, Ultem, PPSU): Lightweight and biocompatible for diverse applications. Lower elastic modulus requires careful workholding and sharp tooling. Thermal expansion concerns during machining and subsequent sterilization cycles.

Aluminum alloys (6061, 7075): Common for medical equipment housings and diagnostic device components. Excellent machinability enables tight tolerances economically. Anodizing for corrosion resistance may affect final dimensions by 0.0001-0.0003″.

Cutting Tool Selection and Condition

Tool geometry, coating, and sharpness profoundly impact accuracy in medical CNC machining. Dull tools generate excessive heat and cutting forces, both detrimental to dimensional accuracy.

Tool material: Carbide tools maintain sharp cutting edges far longer than high-speed steel, providing better dimensional consistency across production runs. Polycrystalline diamond (PCD) tools suit high-volume medical CNC operations in aluminum and plastics, delivering exceptional tool life and surface finish.

Tool geometry: Cutting edge geometry affects cutting forces and heat generation. Properly selected rake angles, clearance angles, and edge preparations minimize deflection and thermal effects preserving dimensional accuracy.

Coatings: TiN, TiCN, TiAlN, and diamond-like carbon coatings reduce friction and heat, extending tool life while improving accuracy consistency. Medical device CNC machining benefits from coated tools that maintain performance longer between tool changes.

Tool runout: Even microscopic runout where tools mount in spindles translates into part dimensional errors. Precision toolholders with TIR under 0.0001″ ensure tool geometry performs as designed.

Systematic tool management including pre-setting, runout measurement, and scheduled replacement based on part count or dimensional trending maintains accuracy throughout production runs.

Environmental Control for Maximum Accuracy

Temperature and humidity variations affect both machines and workpieces, making environmental control essential for extreme precision in medical CNC operations.

Temperature Management

Professional medical CNC machining facilities maintain temperature control typically within ±1°C throughout production areas. More demanding applications require ±0.5°C control or dedicated temperature-controlled measurement rooms for inspection.

Temperature effects on accuracy:

- Aluminum expands/contracts approximately 0.000023″ per inch per °F

- Stainless steel changes approximately 0.0000096″ per inch per °F

- A 10°F temperature swing causes a 10″ aluminum part to change dimension by 0.0023″

Climate-controlled environments prevent these thermal variations from compromising dimensional accuracy. Some facilities machine and inspect parts in the same controlled environment, eliminating temperature-related measurement errors.

Humidity Control

While less critical than temperature for metals, humidity significantly affects plastic materials used in medical device components. Hygroscopic plastics like nylon absorb moisture, causing dimensional swelling. Medical CNC facilities working with plastics maintain humidity control preventing moisture-related dimensional instability.

Measurement and Verification Capabilities

Achievable machining accuracy means little without measurement systems capable of verifying dimensions at the same precision level. Medical CNC operations employ sophisticated metrology equipment matching or exceeding machining capabilities.

Coordinate Measuring Machines (CMM)

CMM systems represent the gold standard for verifying complex three-dimensional geometries in CNC machining medical devices. Modern CMMs achieve measurement uncertainties as low as 1-2 microns (0.00004-0.00008″), enabling verification of the tightest machining tolerances.

CMM capabilities for medical applications:

- Three-dimensional coordinate measurement of complex geometries

- Automated inspection programs ensuring consistent measurement procedures

- Statistical process control integration tracking dimensional trends

- Temperature compensation accounting for thermal effects on parts and machine

- Tactile and optical sensors accommodating different surface types

Bridge-type CMMs handle larger medical equipment components while horizontal-arm designs suit smaller precision parts. Temperature-controlled measurement rooms eliminate thermal errors for critical verifications.

Optical Measurement Systems

Non-contact optical measurement provides advantages for delicate medical components or features inaccessible to tactile probes:

Vision systems: CNC vision systems measure 2D features with sub-micron accuracy, ideal for verifying small holes, edge distances, and profile geometries in medical CNC turning operations.

Laser scanning: Capture complete surface topography for freeform surfaces, organic shapes in surgical instruments, or complex anatomical features in custom implants.

Confocal microscopy: Achieves nanometer-level resolution for critical surface texture verification on bearing surfaces or sealing interfaces.

In-Process Monitoring

Advanced medical CNC machines incorporate in-process gauging providing real-time dimensional feedback:

Tool breakage detection: Sensors immediately detect broken tools preventing continued machining of scrap parts.

Dimensional probing: Touch probes verify critical dimensions during machining cycles, enabling tool offset compensation before completing parts.

Adaptive control: Cutting force and power monitoring detect process variations, adjusting parameters maintaining dimensional consistency despite material or tool variations.

Specialized Techniques for Extreme Accuracy

When applications demand accuracy beyond standard machining capabilities, specialized techniques extend precision limits in medical device CNC machining.

Cryogenic Machining

Liquid nitrogen cooling during cutting operations offers several accuracy advantages:

- Reduced thermal expansion of workpieces maintains dimensional stability

- Extended tool life preserves sharp cutting edges longer

- Decreased built-up edge formation on cutting tools

- Minimized residual stresses in finished components

Medical CNC facilities machining titanium implants or precision surgical instruments employ cryogenic cooling achieving tolerances approaching ±0.0001″ while improving surface finish and material properties.

Multi-Stage Machining Strategies

Extreme precision often requires multiple machining passes with intermediate stress relief:

Rough machining: Removes bulk material rapidly with standard tolerances, releases residual stresses, and establishes approximate geometry.

Stress relief: Thermal treatment relieves machining-induced stresses preventing subsequent dimensional changes.

Semi-finishing: Removes most remaining material approaching final dimensions within 0.005-0.010″ of specifications.

Finishing: Final passes with minimal material removal, sharp tools, and optimized parameters achieve specified tolerances.

This approach prevents stress-related distortion and minimizes heat generation during critical finishing operations where dimensional accuracy matters most.

Temperature-Controlled Machining

Some high-precision medical CNC operations maintain workpieces at constant temperatures throughout machining through heated or cooled fixtures, eliminating thermal expansion/contraction as accuracy variables.

Real-World Accuracy Examples in Medical Applications

Understanding theoretical limits helps less than examining actual medical CNC machining applications and their achieved accuracies.

Orthopedic implant components: Hip and knee replacement components require bearing surfaces flat within 0.0002″ across entire surface areas while maintaining sphericity tolerances of ±0.001″. Medical CNC machining consistently achieves these specifications in cobalt-chrome and titanium alloys.

Surgical instrument assemblies: Laparoscopic instrument jaw mechanisms demand pin holes positioned within ±0.0005″ maintaining precise alignment through assembly. Swiss-type medical CNC turning produces these components meeting stringent tolerances through thousands of production cycles.

Drug delivery device components: Insulin pens and auto-injectors require threaded features with ±0.001″ pitch accuracy and ±0.0005″ concentricity maintaining consistent dosing. CNC machining medical device components achieves these specifications in medical-grade plastics despite thermal expansion challenges.

Diagnostic equipment optics: Blood analyzers incorporate precision optical windows requiring flatness within 2-3 light bands (0.00005″) and parallelism within 30 arc-seconds. Specialized grinding operations within medical CNC facilities meet these demanding optical specifications.

Catheter manufacturing components: Mandrels for catheter extrusion must maintain diameter consistency within ±0.0002″ over 24″ lengths. Precision medical CNC turning with temperature control and specialized grinding achieves these tolerances in hardened tool steel.

Quality Systems Supporting Accuracy

Maintaining advertised accuracy levels throughout production requires robust quality management systems extending beyond individual machine capabilities.

Process Validation and Capability Studies

Medical device manufacturers conduct process capability studies demonstrating that CNC machining for medical industry applications consistently produces parts within specifications:

Cpk values: Process capability indices quantify how well processes perform relative to specification limits. Medical CNC operations typically target Cpk ≥ 1.67 (5-sigma capability) ensuring 99.99966% of parts meet specifications.

Gage R&R studies: Verify that measurement variation remains small compared to specification tolerances, ensuring that measurement error doesn’t mask true part dimensional variations.

Statistical process control: Ongoing monitoring detects process trends before parts exceed specifications, enabling proactive adjustments maintaining dimensional accuracy.

Traceability and Documentation

Medical device regulations require complete traceability linking finished components to specific materials, machines, operators, inspection results, and process parameters. Modern medical CNC machining facilities maintain comprehensive digital records satisfying FDA 21 CFR Part 11 and ISO 13485 requirements.

Accuracy Limitations and Practical Considerations

Despite remarkable capabilities, medical CNC machining faces practical accuracy limits that designers and engineers must understand.

Feature size effects: Extremely small features challenge accuracy disproportionately. A 0.020″ diameter hole held to ±0.0002″ represents 1% tolerance—extremely tight. The same ±0.0002″ tolerance on a 10″ dimension represents just 0.002%—far more achievable.

Depth-to-diameter ratios: Deep, narrow features like small diameter deep holes cannot maintain the same accuracy as shallow features due to tool deflection and access limitations.

Surface finish correlation: Tighter tolerances generally require better surface finishes. Rough surfaces with peaks and valleys make dimensional measurement ambiguous—where exactly does the “dimension” exist on a rough surface?

Cost-accuracy relationship: Accuracy requirements significantly impact costs. Moving from ±0.002″ to ±0.001″ might increase costs 25-50%. Reaching ±0.0002″ could double or triple costs compared to ±0.001″ due to specialized equipment, longer cycle times, and extensive verification.

Specifying Realistic Tolerances

Engineers sometimes specify unnecessarily tight tolerances throughout designs, increasing costs without improving functionality. Best practices for tolerance specification in medical CNC machining include:

Functional analysis: Specify tight tolerances only where functionally necessary. Use standard tolerances elsewhere reducing costs and improving manufacturability.

GD&T application: Geometric dimensioning and tolerancing (GD&T) per ASME Y14.5 standard communicates design intent more effectively than simple plus/minus tolerances, often enabling looser specifications while ensuring functional requirements.

Supplier consultation: Experienced medical device CNC machining suppliers provide valuable input during design phases, suggesting tolerance adjustments that maintain functionality while improving manufacturability.

Material consideration: Account for post-machining processes affecting dimensions—heat treatment, stress relief, coating, sterilization—when establishing initial machining tolerances.

Conclusion

Medical CNC machining routinely achieves remarkable accuracy levels, with standard operations holding ±0.001″ (±0.025mm) tolerances and specialized techniques reaching ±0.0001″ (±0.0025mm) or tighter under controlled conditions. These capabilities enable production of surgical instruments, implantable devices, diagnostic equipment, and drug delivery systems meeting the medical industry’s demanding precision requirements.

However, achieving these accuracy levels requires far more than capable machines. Success depends on quality equipment properly maintained, appropriate tooling selection and management, suitable materials and workholding strategies, environmental control minimizing thermal effects, sophisticated measurement systems verifying results, and comprehensive quality management systems ensuring consistency.

Understanding the factors influencing accuracy, the specialized techniques extending precision limits, and the practical considerations affecting achievable tolerances helps medical device manufacturers, engineers, and procurement professionals make informed decisions. Specifying appropriate tolerances—tight where functionally necessary, standard where adequate—optimizes the balance between performance requirements and economic realities.

As medical devices become increasingly sophisticated and miniaturized, medical CNC accuracy will continue advancing. Today’s extreme tolerances will become tomorrow’s standard capabilities, enabling medical innovations that improve patient outcomes and advance healthcare delivery. The fundamental principles governing accuracy—equipment quality, process control, environmental management, and measurement capability—will remain cornerstones of precision medical device manufacturing regardless of how technology evolves.

FAQs

How do shops keep machines from drifting during long runs?

They regulate room temperature, monitor spindle heat, and cut in short “kiss” passes to control tool pressure.

Is five-axis always more accurate than Swiss turning?

Not always—Swiss wins on slender parts, while five-axis excels on complex faces. Both can hit microns when tuned.

Can small clinics afford micron-grade parts?

Yes. Automation and smart quoting have made affordable medical CNC machining widely available, even for limited orders.

Why not just 3D-print implants?

Metal printing lags behind in surface finish and repeatable tolerances; machining still rules for critical fits.

What metals are hardest to machine to micron accuracy?

Cobalt-chrome alloys challenge cutters, but with diamond tools and careful feeds, microns are still achievable.