Manufacturing has undergone a remarkable transformation over the past few decades, and CNC laser cutting stands at the forefront of this revolution. This precision technology combines computer numerical control with focused laser beams to cut, engrave, and shape materials with extraordinary accuracy. Whether you’re a manufacturer exploring production options, an engineer designing components, or simply curious about modern fabrication methods, understanding CNC laser cutting technology reveals how today’s products achieve their precise dimensions and intricate designs.

Table of Contents

What Is CNC Laser Cutting?

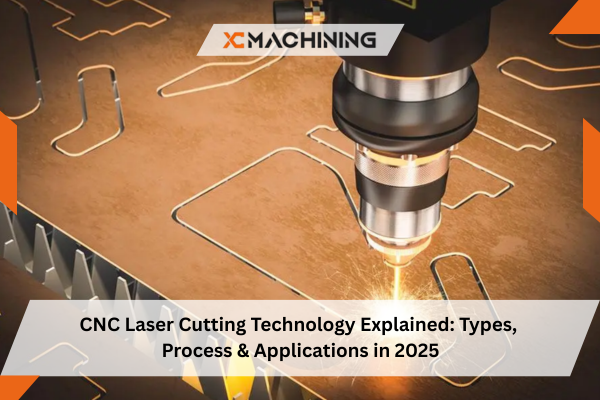

CNC laser cutting is an advanced manufacturing process that uses a high-powered laser beam controlled by computer systems to cut through various materials. The “CNC” (Computer Numerical Control) aspect means that computers direct every movement of the laser head according to programmed instructions, typically derived from CAD (Computer-Aided Design) files.

The process works by focusing a laser beam into an extremely small, intense point of light. This concentrated energy heats the material to its melting or vaporization point, creating a precise cut as the laser moves along the programmed path. An assist gas—typically oxygen, nitrogen, or compressed air—blows away molten material and prevents oxidation, resulting in clean, burr-free edges.

Modern CNC laser cutting machines achieve tolerances as tight as ±0.1mm, making them indispensable for industries requiring precision components. From aerospace brackets to decorative architectural panels, this technology handles an impressive range of applications that would be difficult, time-consuming, or impossible with traditional cutting methods.

Types of CNC Laser Cutting Machines

The CNC laser cutting market offers several distinct machine types, each optimized for specific materials and applications. Understanding these differences helps manufacturers select the right equipment for their needs.

CO2 Laser Cutting Machines

CO2 lasers generate their beam through an electrically stimulated mixture of carbon dioxide gas. These versatile machines excel at cutting non-metallic materials and have been industry workhorses for decades.

Optimal materials for CO2 lasers:

- Acrylic and plastics

- Wood and wood composites

- Fabrics and leather

- Paper and cardboard

- Rubber materials

- Thin metals (with higher power units)

CO2 laser cutting systems typically operate at wavelengths around 10.6 micrometers, which many organic materials readily absorb. This makes them particularly efficient for cutting thicker non-metal materials. Many mini CNC laser cutting machines use CO2 technology because it provides excellent results for small businesses, craft applications, and prototyping work at relatively affordable price points.

Fiber Laser Cutting Machines

Fiber lasers represent the newer generation of cutting technology, using optical fibers doped with rare-earth elements to generate the laser beam. These systems have rapidly gained market share, particularly for metal cutting applications.

A CNC fiber laser cutting machine supplier will emphasize several key advantages:

- Superior metal cutting performance: Fiber lasers cut reflective metals like aluminum, copper, and brass more effectively than CO2 systems

- Higher electrical efficiency: Converting 30-40% of input power to laser output versus 10-15% for CO2 lasers

- Lower maintenance requirements: Solid-state design with fewer consumable parts

- Faster cutting speeds: Particularly noticeable in thin to medium-thickness metals

- Smaller focused spot size: Enabling finer details and tighter tolerances

Industrial CNC laser cutting machines increasingly utilize fiber laser technology for metal fabrication shops, automotive component manufacturing, and electronics production. The technology operates at approximately 1.06 micrometers wavelength, which metals absorb much more efficiently than the longer CO2 wavelength.

Crystal Laser Cutting Machines

Crystal lasers (Nd:YAG and Nd:YVO) use neodymium-doped crystals as the laser medium. While less common than CO2 and fiber systems, they occupy a niche in specialized applications requiring particular characteristics.

These machines handle both metals and certain non-metals, offering versatility that bridges CO2 and fiber laser capabilities. However, their higher maintenance costs and lower efficiency compared to fiber lasers have limited their adoption in recent years.

The CNC Laser Cutting Process Step-by-Step

Understanding how CNC laser cutting works reveals why this technology produces such consistent, high-quality results.

1. Design and Programming

The process begins with creating or importing a digital design file, typically in formats like DXF, DWG, or SVG. Computer-Aided Manufacturing (CAM) software converts these designs into G-code—the numerical control language that CNC machines understand.

During programming, operators specify crucial parameters:

- Cutting speed and power settings

- Assist gas type and pressure

- Pierce points and lead-in/lead-out strategies

- Tool path optimization for efficiency

- Nesting arrangements to minimize material waste

2. Material Preparation and Setup

Operators secure the workpiece material onto the cutting bed, ensuring it lies flat and properly positioned. Modern industrial CNC laser cutting machines often feature automated material handling systems that load sheets, position them precisely using cameras or sensors, and remove finished parts.

Proper material preparation prevents issues during cutting. Sheet materials must be clean, dry, and free from excessive oil or contaminants that could interfere with the cutting process or damage optics.

3. Calibration and Focusing

Before cutting begins, the system calibrates the focal length—the distance between the laser head and material surface. This critical parameter affects cut quality significantly. Too close or too far from optimal focus results in wider kerf (cut width), rough edges, or incomplete cutting.

Automatic focusing systems on advanced machines continuously adjust the focal position as the laser head moves across the material, compensating for any variations in sheet flatness or thickness.

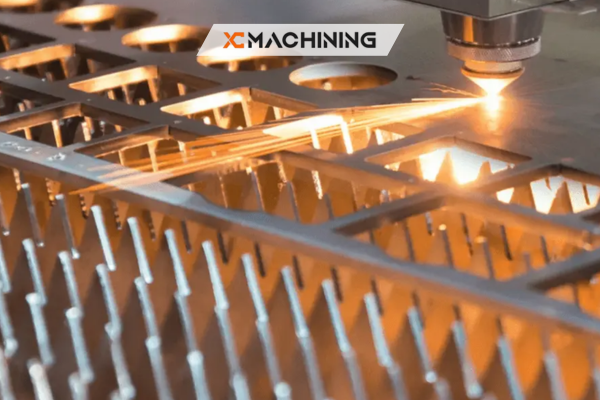

4. Laser Cutting Execution

With everything configured, the actual cutting begins. The laser beam heats the material to its melting or vaporization point while assist gas blows through the cut zone. Different assist gases serve specific purposes:

Oxygen: Creates an exothermic reaction with steel, actually adding heat to the cutting process for thicker materials. Produces oxide layers on cut edges.

Nitrogen: Provides inert shielding that prevents oxidation, creating clean, bright edges ideal for stainless steel and aluminum. Required for parts needing painting or welding without additional preparation.

Compressed air: Economical option for less demanding applications and non-metallic materials.

The CNC system precisely controls laser power throughout the cut. Corners may require power reduction to prevent overheating, while straight sections can run at maximum speed and power for efficiency.

5. Part Removal and Finishing

After cutting completes, finished parts are removed from the bed. Depending on the application, minimal or no additional finishing may be required—one of CNC laser cutting’s major advantages. When necessary, light deburring or surface treatment provides the final touch.

Applications Across Industries

CNC laser cutting services have become essential across virtually every manufacturing sector due to the technology’s versatility and precision.

Manufacturing and Industrial Applications

Metal fabrication shops rely on industrial CNC laser cutting machines for producing brackets, enclosures, chassis, and structural components. The automotive industry uses laser cutting for body panels, exhaust components, and interior trim pieces. Agricultural equipment manufacturers cut complex shapes for machinery components that traditional methods struggle to produce economically.

Architecture and Construction

Architectural metalwork showcases laser cutting’s artistic capabilities. Decorative screens, façade panels, stair railings, and signage feature intricate patterns impossible to achieve with conventional cutting. The technology cuts expansion joints, mounting brackets, and custom hardware with repeatable precision.

Electronics and Technology

Circuit board production, device enclosures, heat sinks, and shielding components benefit from laser cutting’s ability to create small, precise features without mechanical stress that could damage delicate electronics. The non-contact nature of laser cutting prevents warping in thin materials.

Medical Device Manufacturing

Medical instruments, surgical tools, and implantable device components require the biocompatible cutting that laser technology provides. The process produces burr-free edges critical for medical applications, and the narrow heat-affected zone minimizes material property changes.

Signage and Advertising

From illuminated channel letters to dimensional logos and display fixtures, the signage industry extensively employs both mini CNC laser cutting machine for small shops and industrial systems for large-scale production. Multiple materials—acrylic, aluminum, stainless steel, wood—can be cut on the same machine.

Aerospace and Defense

Aerospace components demand the tight tolerances and traceability that CNC laser cutting delivers. Turbine parts, structural brackets, panel components, and interior fittings must meet stringent specifications that laser cutting consistently achieves.

Advantages of CNC Laser Cutting Technology

Several compelling benefits explain why manufacturers increasingly adopt laser cutting:

Exceptional precision and accuracy: Tolerances of ±0.1mm or better enable production of parts that fit together perfectly without adjustment.

No tool wear: Unlike mechanical cutting where blades dull and require replacement, laser beams don’t wear out, ensuring consistent quality throughout production runs.

Minimal material waste: Tight nesting of parts and narrow kerf widths maximize material utilization, reducing costs and environmental impact.

Complex geometry capability: Intricate curves, small internal cutouts, and detailed patterns present no additional difficulty compared to simple shapes.

Fast setup and changeover: Switching between different parts requires only loading a new program—no physical tooling changes needed.

Reduced secondary operations: Clean edges often eliminate deburring, and precise dimensions may eliminate fitting and adjustment steps.

Automation compatibility: Modern systems integrate with robotic loading/unloading, automatic sorting, and material handling systems for lights-out manufacturing.

Selecting the Right CNC Laser Cutting Solution

Choosing appropriate equipment depends on your specific requirements and production environment.

For Small Businesses and Startups

A mini CNC laser cutting machine provides an accessible entry point for entrepreneurs, small fabrication shops, and prototyping operations. These compact systems typically feature:

- Working areas from 300x300mm to 1000x600mm

- Power outputs between 40-150 watts for CO2 systems or 500-1500 watts for fiber

- Manual or semi-automatic material handling

- Price points ranging from $3,000 to $30,000

These machines handle signage, crafts, prototypes, and small production runs effectively without the space and capital requirements of industrial systems.

For Production Manufacturing

Industrial CNC laser cutting machines designed for high-volume production incorporate:

- Large working envelopes (1500x3000mm to 2000x6000mm or larger)

- High-power lasers (1000-30,000 watts for fiber systems)

- Automated sheet loading and part removal

- Advanced process monitoring and quality control systems

- Integration with factory management software

Working with a reputable CNC fiber laser cutting machine supplier ensures proper system specification, installation support, operator training, and ongoing technical assistance.

Accessing CNC Laser Cutting Services

Not every business needs to invest in equipment ownership. Professional CNC laser cutting services provide on-demand access to advanced technology without capital investment. These services suit businesses with:

- Fluctuating production volumes

- Limited facility space

- Occasional specialized material requirements

- Need for multiple technology types (fiber and CO2)

Service providers typically offer quick turnarounds, material procurement, and finishing services, handling the complete production process from your digital files to finished parts.

The Future of CNC Laser Cutting

As we progress through 2025, several trends are shaping CNC laser cutting technology’s evolution. Artificial intelligence integration helps optimize cutting parameters automatically, improving efficiency and quality while reducing operator expertise requirements. Enhanced automation continues reducing labor costs and enabling 24/7 production capabilities.

Hybrid machines combining laser cutting with other processes like bending, welding, or additive manufacturing create complete fabrication cells that minimize material handling. Improved energy efficiency reduces operating costs while supporting sustainability initiatives. Cloud connectivity enables remote monitoring, predictive maintenance, and centralized management of multiple machines across different locations.

Conclusion

CNC laser cutting technology has fundamentally changed how manufacturers approach material cutting and fabrication. The combination of precision, speed, versatility, and automation makes it indispensable across countless industries. Whether you’re considering a mini CNC laser cutting machine for a startup venture, specifying an industrial system for high-volume production, or partnering with CNC laser cutting services for your component needs, this technology offers solutions that traditional cutting methods simply cannot match.

Understanding the different laser types, process parameters, and application possibilities helps you make informed decisions about incorporating this powerful technology into your manufacturing operations. As systems become more capable and accessible, CNC laser cutting will continue expanding into new applications, driving innovation in product design and manufacturing efficiency.