At XC Machining, we provide top-notch injection molding services tailored to meet the various needs of our clients across several industries. Our commitment to quality, efficiency, and innovation sets us apart in the competitive landscape of manufacturing. With a focus on precision and customer satisfaction, we ensure that each project is handled with the utmost care and expertise. Injection molding is not just a manufacturing process; it is a gateway to creating high-quality, complex parts with exceptional consistency.

Key benefits of choosing our injection molding services:

High Repeatability

- Consistent Quality: Our injection molding process guarantees uniform product quality, ensuring that every part meets your specifications, even in large production volumes. This high repeatability minimizes waste and maximizes efficiency.

Material Diversity

- We offer an extensive selection of materials suitable for various applications. Whether you need durable plastics for automotive components or flexible materials for consumer electronics, our team can guide you in selecting the optimal material based on your specific requirements.

Cost-Effectiveness

- Injection molding is particularly advantageous for large-scale production. While the initial setup costs may be higher, the per-unit cost decreases significantly as production volume increases, making it a cost-effective solution for your manufacturing needs.

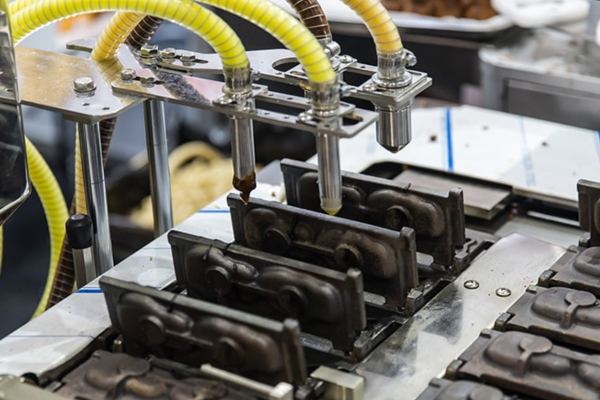

Intricate Part Production:

Our advanced injection molding techniques allow us to produce intricate parts that often eliminate the need for additional assembly. This capability not only streamlines production but also enhances product integrity.

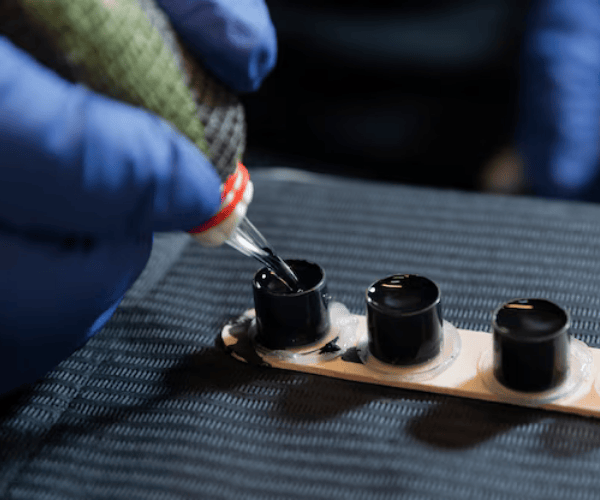

Multi-Material Integration

- Utilizing overmolding techniques, we can incorporate multiple materials into a single part. This integration improves both functionality and aesthetics, providing you with innovative solutions that stand out in the market.

Rapid Prototyping

- With low-cost tooling options, we can produce rapid injection molded prototypes in as fast as 10 business days. This speed allows you to test designs and make adjustments quickly, accelerating your product development cycle.

Versatile Production Capabilities:

- Whether you require low-volume production of 250 units or mass production exceeding 1,000,000 units, our injection molding services are designed to accommodate your needs. Our CNC machined molds ensure high precision and tolerance levels between +/-0.001″ and 0.005″.

Range of Industries Served

- Diverse Applications: We cater to a variety of industries including automotive, aerospace, energy, industrial machinery, electronics, and communications. Our expertise ensures that we meet the specific standards and requirements of each sector.

Variety of Materials

- Custom Material Selection: Our extensive knowledge allows us to recommend materials that provide impact resistance, chemical stability, rubber-like elasticity, and dimensional accuracy. We can source thousands of custom materials upon request to ensure your project’s success.

Single and Multi-Cavity Molds

- Optimized Tooling Solutions: No matter the scale of your project, we offer tailored tooling solutions including single molds for small runs and multi-cavity molds for larger quantities. This flexibility helps reduce costs per part while increasing production speed.

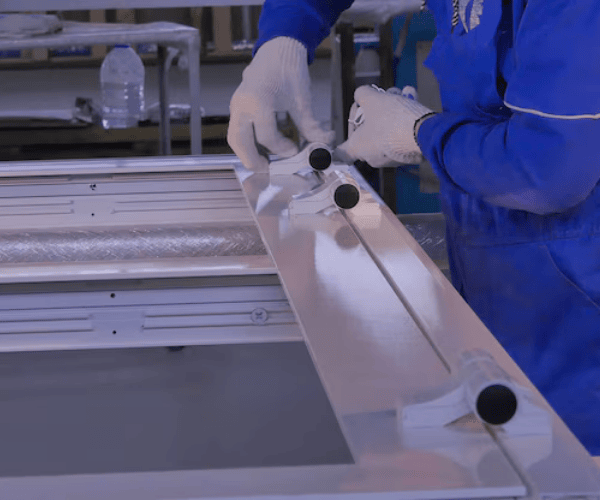

High-Quality Standards

- Rigorous Quality Management: Every part produced through our injection molding services undergoes strict quality management processes. We collaborate with thoroughly vetted suppliers to ensure that all components meet industry-specific certifications and standards.

Choosing XC Machining for your prototype plastic injection molding needs means partnering with a dedicated team focused on delivering exceptional results tailored to your specifications. We understand the challenges faced by businesses today and strive to provide solutions that not only meet but exceed expectations.

Reach out today to achieve your manufacturing objectives while ensuring quality and cost-effectiveness at every step of the process.