Running a business involves juggling multiple tasks, especially when it comes to manufacturing. Delays and inconsistencies can disrupt your workflow and affect your bottom line. This is where jigs and fixtures come into play. They are essential tools that can streamline your manufacturing process, ensuring accuracy and efficiency. Whether you’re managing a small workshop or a large production line, understanding jigs and fixture can give your business a significant advantage. In this blog, we’ll explore what jig and fixtures are, how they work, and why your business needs them.

Let’s break down these tools and see how they can enhance your operations, making your manufacturing process smoother and more reliable.

What Are Jigs and Fixtures?

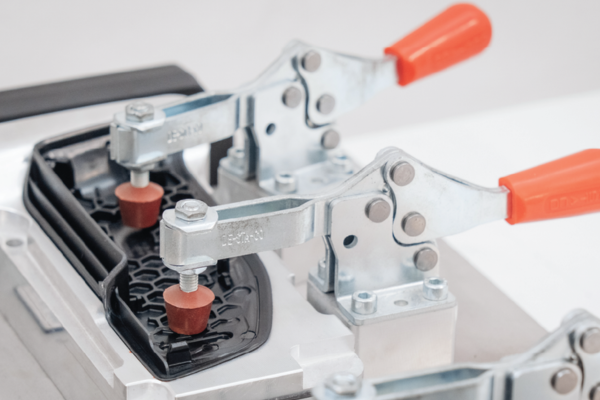

Jigs and fixtures are specialized tools used in manufacturing to hold and guide parts during production. A jig guides the cutting tool, ensuring that operations like drilling or milling are precise every time. On the other hand, a CNC fixture holds the workpiece securely in place, preventing any movement during the manufacturing process. This distinction is crucial because while jigs focus on guiding tools, fixtures focus on stabilizing the workpiece.

By using jigs and fixtures, manufacturers can achieve consistent results, reducing the likelihood of errors and improving the overall quality of the products. These tools are versatile and can be customized to fit various manufacturing needs, making them indispensable in industries ranging from automotive to electronics.

Types of Jig and Fixture

There are various types of jigs and fixtures, each designed for specific tasks in manufacturing. Understanding these types can help you choose the right tools for your needs. Common types include:

- Drill Jigs: Guide drills to create precise holes.

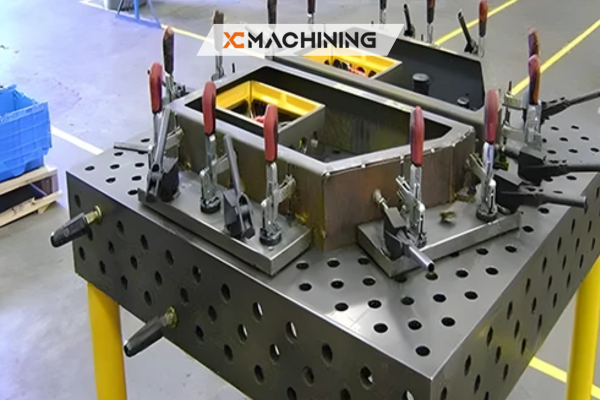

- Welding Fixtures: Hold parts in place for accurate welding.

- Assembly Fixtures: Assist in putting together different components.

- Inspection Jigs: Help in checking the quality and dimensions of parts.

Each type serves a unique purpose, making them versatile tools in any production line. For example, drill jigs ensure that holes are drilled at exact angles and positions, which is crucial for parts that need to fit together seamlessly. Welding fixtures hold components steady, ensuring strong and accurate welds every time. By selecting the appropriate type of jig or fixture, you can enhance the efficiency and accuracy of your manufacturing process, addressing specific challenges and improving overall productivity.

How Do They Work?

Jigs and fixtures work by providing a stable and accurate method to hold and guide parts during the manufacturing process. A jig ensures that the cutting tool follows a precise path, which is essential for operations like drilling holes in exact locations. This guidance eliminates guesswork and manual adjustments, leading to higher precision. Fixtures, meanwhile, secure the workpiece firmly, ensuring it doesn’t move or shift while being worked on.

This stability is vital for maintaining the integrity of the manufacturing process, as even slight movements can result in defects. Together, jig and fixture streamline the production process, allowing for faster and more reliable manufacturing. By maintaining consistent positioning and guidance, these tools help achieve uniformity across all products, which is key for meeting quality standards.

Benefits for Your Business

Implementing jigs and fixtures in your manufacturing process offers numerous benefits that can significantly impact your business:

- Consistency: Ensures every product is made the same way, reducing variability.

- Efficiency: Speeds up the manufacturing process by automating tasks.

- Quality: Improves product standards by minimizing errors.

- Cost Savings: Reduces waste and the need for rework.

- Safety: Provides a stable setup, lowering the risk of accidents.

These advantages contribute to a more streamlined and reliable production process. Consistent quality leads to higher customer satisfaction, while increased efficiency allows you to produce more in less time. Cost savings from reduced waste and rework can improve your bottom line, making your business more profitable. Additionally, a safer workplace enhances employee well-being and reduces the likelihood of workplace injuries. Overall, jigs and fixtures help create a more efficient, cost-effective, and high-quality manufacturing environment.

Improving Product Quality

Quality is essential for maintaining customer satisfaction and loyalty. Jigs and fixtures play a crucial role in enhancing product quality by ensuring each part is manufactured accurately. When parts are consistent and precise, the final product meets high standards of reliability and durability. This consistency helps build your brand’s reputation for quality, making customers more likely to return and recommend your products to others.

Additionally, fewer errors mean fewer defects, which reduces the likelihood of returns and repairs. High-quality products also lead to fewer complaints and lower warranty costs, saving your business time and money. By maintaining strict quality control with jigs vs fixtures, you can ensure that your products consistently meet or exceed customer expectations.

Boosting Efficiency

Efficiency is all about getting more done in less time, and jigs and fixtures are perfect for this. By automating the positioning and guiding of tools, these devices speed up the manufacturing process. Workers can focus on other tasks instead of constantly adjusting materials. This streamlined workflow leads to faster production times and higher output.

Moreover, jigs and fixtures reduce the need for repetitive measurements and adjustments, minimizing downtime. A more efficient production line means you can meet deadlines more easily and take on larger orders without compromising quality. Ultimately, boosting efficiency helps your business operate smoothly and respond quickly to market demands, giving you a competitive edge in the aerospace industry.

Choosing the Right Jigs and Fixtures

Selecting the right jigs and fixtures is crucial for maximizing their benefits. Here are some tips to help you choose:

- Assess Your Needs: Identify which tasks in your production line need improvement.

- Consider Compatibility: Ensure the jigs and fixtures work with your existing machinery.

- Evaluate Quality: Invest in durable, high-quality tools to ensure longevity and reliability.

- Customization: Look for options that can be tailored to your specific manufacturing processes.

- Budget: Balance the cost with the features and benefits you require.

By carefully evaluating these factors, you can find the jigs and fixtures that best fit your business requirements. Customizable options can provide a perfect fit for unique manufacturing challenges, while high-quality tools ensure consistent performance over time. Keeping your budget in mind helps you make a smart investment without overspending. The right selection process ensures that you get the most out of your jigs and fixtures, enhancing your production line effectively and supporting your business goals.

Implementing Them in Your Workflow

Integrating jigs and fixtures into your workflow might seem challenging, but it’s manageable with the right approach. Start by identifying the areas in your production process that would benefit the most from these tools. Next, train your staff on how to use them properly to ensure maximum efficiency and safety. It’s also important to regularly maintain and inspect your jig and fixture to keep them in good working condition.

Gradually incorporating these CNC cutting tools allows you to streamline your operations without disrupting your existing workflow. Over time, the benefits of using jigs and fixtures, such as increased accuracy and faster production, will become evident. This seamless implementation can lead to a more organized and productive manufacturing environment, enhancing overall business performance.

Real-World Success Stories

Many businesses have seen significant improvements by using jigs and fixtures. For instance, a local furniture manufacturer struggled with inconsistent piece sizes, leading to customer dissatisfaction. After implementing custom jig and fixture, their production became more accurate, and customer satisfaction improved markedly. Another example is an automotive parts company that saw a 25% increase in efficiency by using fixtures to hold components during assembly. These success stories demonstrate how jig and fixture can make a real difference in various industries. By learning from these examples, you can understand the tangible benefits these tools bring, encouraging you to integrate them into your own business. These real-world applications highlight the practical advantages and effectiveness of using jigs and fixtures in manufacturing.

Cost Savings Explained

Investing in jigs and fixtures can lead to significant cost savings for your business. Here’s how:

- Reduced Waste: Precise manufacturing means fewer mistakes, leading to less wasted material.

- Lower Labor Costs: Automated processes require less manual intervention, reducing labor expenses.

- Decreased Rework: Consistent quality minimizes the need to fix or redo parts, saving both time and money.

- Extended Tool Life: Properly guided tools experience less wear and tear, lowering maintenance costs.

For example, a business might save up to 30% on material costs by minimizing waste through precise manufacturing. Additionally, faster production times can increase output without the need to hire more staff, further reducing labor costs. By decreasing the need for rework, businesses can avoid the expenses associated with correcting errors. Moreover, tools that are well-guided by jig and fixture last longer, reducing the frequency and cost of replacements. These savings add up, making the initial investment in jigs and fixtures a smart financial decision for any manufacturing business.

One Important Fact

Did you know that businesses using jigs and fixtures can reduce production time by up to 50%?

This significant improvement means faster turnaround times and the ability to handle more orders without compromising quality. Such a reduction in production time not only boosts efficiency but also enhances your ability to meet customer demands promptly. This fact alone showcases the transformative impact jigs and fixtures can have on your manufacturing process, making them a worthwhile investment for any business looking to optimize its operations. By cutting down production time, your business can increase output, improve customer satisfaction, and stay competitive in the market.

The Future of Manufacturing with Jig and Fixture

As technology advances, the role of jigs and fixture Part Manufacturing is becoming even more important. Modern jigs and fixture are now designed with automation and precision in mind, integrating seamlessly with advanced machinery and computer systems. This evolution allows for even greater accuracy and efficiency, pushing the boundaries of what’s possible in production. Additionally, innovative materials and designs are making jigs and fixtures more durable and adaptable, enhancing their functionality and lifespan.

Staying updated with these advancements ensures your business remains competitive in a rapidly changing market. Embracing the future of jigs and fixtures can lead to continuous improvement and sustained success in your manufacturing endeavors, keeping your operations ahead of the curve.

Training Your Team for Success

Having the right tools is only part of the equation; ensuring your team knows how to use them effectively is equally important. Training your staff on the proper use of jigs and fixtures can maximize their benefits and prevent misuse. Start with basic training sessions that cover the fundamentals of each tool. Demonstrate how to set up and adjust jig and fixture for different tasks. Encourage hands-on practice to build confidence and proficiency.

Regular training updates can keep your team informed about any new tools or techniques. Additionally, fostering a culture of continuous learning can lead to ongoing improvements in your manufacturing process. Well-trained employees are more efficient, make fewer mistakes, and contribute to a safer workplace, enhancing the overall success of your business.

Maintenance and Longevity

To ensure that your jigs and fixtures provide long-term benefits, proper maintenance is essential. Regular inspections can help identify any wear and tear or potential issues before they become serious problems. Clean the tools after each use to prevent the buildup of debris that can affect their performance. Lubricate moving parts as needed to ensure smooth operation. Store jigs and fixtures in a safe, dry place to protect them from damage.

Implement a maintenance schedule that includes routine checks and servicing. By taking these steps, you can extend the lifespan of your jig and fixture, ensuring they continue to perform accurately and reliably. Proper maintenance not only preserves the quality of your tools but also safeguards your investment, providing ongoing support for your manufacturing process.

Conclusion

Jigs and fixtures are indispensable tools for any business involved in CNC machining. They ensure consistency, improve quality, boost efficiency, and lead to significant cost savings. By holding and guiding parts accurately, these tools minimize errors and streamline the production process, allowing your business to produce high-quality products more quickly and reliably.

Investing in the right jigs and fixtures tailored to your specific needs can transform your operations, making them more efficient and competitive. As technology continues to evolve, the importance of jigs will only grow, offering even more benefits to businesses that embrace them. Are you ready to take your manufacturing process to the next level with jig and fixture?

FAQs

How Do Jigs and Fixtures Affect Production Scalability?

By standardizing processes, they allow your manufacturing operations to handle larger volumes without compromising quality. As demand increases, jigs and fixtures ensure that each product is produced consistently, making it easier to ramp up production. This scalability means you can meet higher order quantities efficiently.

What are the initial costs of implementing jigs and fixtures?

Initial costs vary based on complexity and customization. However, the long-term savings from reduced waste, increased efficiency, and improved quality often offset the upfront investment.

Can jigs and fixtures be integrated into existing production lines?

Absolutely. They can be adapted to fit current workflows, enhancing existing processes without major overhauls. Proper planning ensures smooth integration and maximizes their benefits.