If you need to fabricate metal parts quickly and with great accuracy, chances are that you have mastered the art of laser cutting stainless steel. What industries do you think utilize it the most? Have you ever thought about its breadth of popularity? Either you’re looking for elaborate custom brackets for a larger assembly, or laser cutting equipped with intricate sculpting abilities fascinates you.

To summarize, laser cutting stainless steel shifts the baseline on what is achievable in terms of goods manufactured from metal materials. It is famous because it can scoop out populated materials, either in the form of sheets that are thick or thin, with precision that is considered surgical while leaving behind only minimal burrs or rough edges. The scope is almost limitless, from car parts to even fragile kitchen accessories. In this blog post, we will more closely investigate what laser cutting means in stainless steel construction.

Laser Cutting Stainless Steel: Understand The Basics

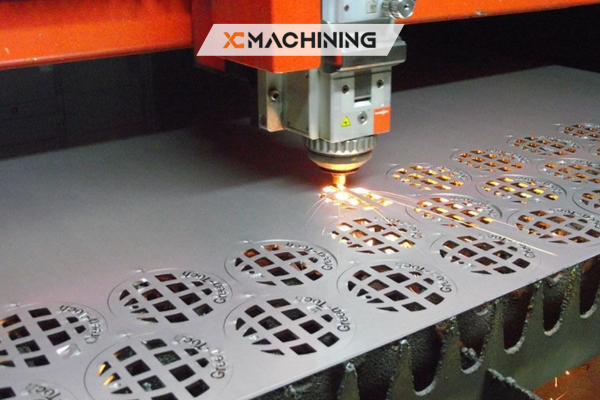

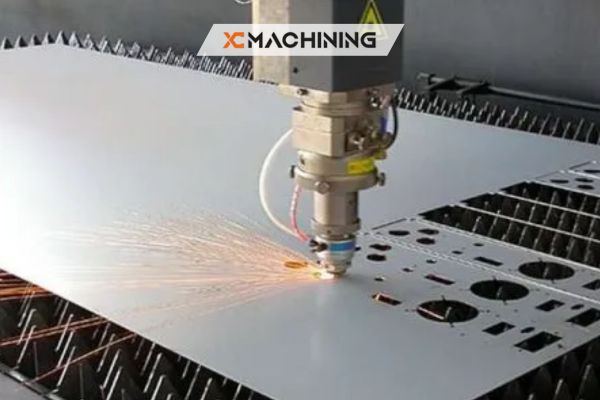

Laser cutting stainless steel is a technology or process of directing a focused beam of light on metal for it to be cut or engraved with target edges that are clear and clean. This cutting technology can be applied to auto parts, industrial machines, kitchen devices, medical instruments, and even works of art. Fast speeds, minimal waste, and high repeatability make laser cutters a favorite across multiple industries.

Precision Matters

Laser beams create exceptionally clean cuts, often without additional finishing. That precision comes from tightly focused energy that melts or vaporizes only the metal in the beam’s path. This translates into better fitting parts, whether in mass production or custom jobs.

Speed And Efficiency

Automated laser cutting machines move quickly, handling complex shapes without manual retooling. Higher speeds mean more parts are produced per hour. The efficient design also cuts down on wasted material, saves money on raw steel sheets, and reduces environmental impact.

Versatility Across Thicknesses

From thin stainless steel foils to plates inches thick, laser cutters adapt well. Operators can adjust power levels and cutting speeds to suit a wide range of thicknesses. This versatility makes them invaluable for industries needing both delicate and heavy-duty parts.

The Automotive Sector

Laser cutting isn’t limited to futuristic labs or small artisan shops. In the automotive world, laser cutting stainless steel helps produce car frames, exhaust systems, engine components, and decorative trim. Major car manufacturers rely on lasers for:

- Body Panels: They can quickly shape fenders or door panels with minimal distortion.

- Chassis Parts: Lasers form welded sections, brackets, and reinforcements with repeatable precision.

- Exhaust Systems: The smooth edges from laser cutting reduce rough spots that might trap debris or impact flow.

Automotive companies appreciate how laser technology seamlessly handles prototypes and large-scale production. This approach keeps cars safer and more aerodynamic while minimizing manual labor. A big plus is how easily laser programs can switch from one model or part size to another. That flexibility speeds up design changes, a must in a fast-moving industry.

Quick Tip: For parts exposed to road salt or heat, stainless steel offers corrosion resistance. Laser cutting preserves that advantage by keeping the metal’s protective chromium oxide surface intact.

Industrial Machinery And Equipment

Factories use laser cutting stainless steel for everything from gear housings to specialized conveyor components. In many cases, these stainless steel parts must hold up under heavy mechanical stress or continuous operation.

One prime example is the food processing sector. Stainless steel is ideal since it resists rust and contamination, which is crucial for hygiene. Laser cutters create washers, bolts, and machine frames with millimeter-perfect tolerance.

Another application is oil and gas machinery. Large, rugged pumps or valves often require thick metal sections. Thanks to high-power laser systems, cutting these robust parts is more efficient and precise than older methods like plasma or waterjet.

Warnings: Always ensure your stainless steel sheets match the laser’s maximum recommended thickness. Overloading a machine might degrade cutting quality or damage the equipment.

Kitchenware And Appliances

Ever notice how laser cutting stainless steel pots, pans, and cutlery have smooth edges and sleek designs? Laser cutting plays a huge role in manufacturing these kitchen essentials. Because stainless steel is durable and easy to sanitize, it dominates the cooking industry.

Consider flatware production. Knife blades, spatula heads, and even decorative patterns on spoons can be lasered from thin steel sheets. This approach saves time and ensures each utensil is consistent in shape and weight.

Appliance manufacturers also benefit. Microwave interiors, dishwasher racks, and refrigerator panels often come from laser-cut stainless steel. The result is a polished, uniform look that stands up to repeated use and cleaning chemicals.

Info: Polishing or electropolishing processes can follow laser cutting technology. These finishing touches refine edges further, boosting overall appeal and usability in kitchen products.

Medical And Laboratory Tools

Medicine demands cleanliness and precision. Laser cutting stainless steel meets these high standards by crafting surgical instruments, implant components, and lab hardware. Since stainless steel resists corrosion and can be sterilized at high temperatures, it’s a favorite for hospital settings.

Tiny scalpels, forceps, or biopsy tools can be laser-cut with micrometer-level detail. That detail is vital when a surgeon needs steady, reliable equipment. Equally important are stainless steel trays or stands that hold instruments during procedures, ensuring no contamination or mechanical failures arise.

Even specialized lab equipment relies on stainless steel. Microfluidic channels or sensor housings might require tight tolerances. Laser cutting can form extremely narrow slits or holes without burrs, maintaining the integrity of sensitive experiments.

Suggestion: If you produce medical parts, consider a sterile environment after cutting. Residual metal dust or oils should be removed thoroughly, often via ultrasonic cleaning or passivation.

Decorative And Architectural Projects

Stainless steel isn’t all about rugged functionality. Design enthusiasts also harness its modern, reflective surface for art installations, building facades, and interior décor. Laser cutting fosters creativity by translating intricate designs onto steel panels or sculptures.

Take interior architecture, for instance. Laser-cut stainless steel screens or partitions can cast playful shadows and brighten a space with their reflective finish. Restaurants, hotels, and upscale lobbies utilize these metal “screens” to add a stylish flair.

Even small signage benefits. Companies often want durable, eye-catching signs for their storefronts. Using laser cutting stainless steel ensures crisp lettering and a professional finish that endures weather, time, and vandalism better than many alternatives.

When you combine stainless steel’s sleek look with the accurate lines of metal laser cutting design, you get statement pieces that stand out—be it a corporate lobby sign or a public sculpture.

Aviation And Aerospace

In planes and spacecraft, weight matters. Laser cutting thrives here because it carves out exact shapes from thin stainless steel sheets, minimizing wasted material. By controlling weight, engineers can improve fuel efficiency or flight performance.

Aircraft Interiors

Seats, overhead bins, and even cabin signage might use stainless steel for structural or decorative elements. Lasers help produce these parts quickly, ensuring standardization across fleets.

Engine Components

Certain engine or turbine elements call for high heat resistance. Stainless steels with specific alloys can handle these extremes. Laser cutters produce neat edges that reduce stress points, an advantage in any high-speed mechanical setting.

Aerospace Prototyping

When designing experimental crafts or satellites, quick turnaround is everything. Laser cutting shortens lead times by allowing engineers to test new stainless steel components on the fly. If a part fails, you can revise the CAD file and recut it in hours, not days.

Danger: The aerospace sector demands strict compliance with material traceability. Ensure every stainless steel sheet has the right certifications before feeding it into a laser cutting machine.

Advantages And Limitations Table

Below is a table highlighting the key pros and potential challenges of laser cutting stainless steel. This format can help you weigh your options if you’re deciding whether it’s the right process for your next project.

| Aspect | Advantage | Limitation |

|---|---|---|

| Edge Quality | Smooth, minimal finishing needed | It may need post-processing if thicker steel is cut |

| Precision | High accuracy for detailed parts | Setup costs might be higher for specialized lasers |

| Speed | Rapid cutting is beneficial for large volumes | Overly thick metal can slow the process |

| Material Waste | Slim kerf width, less scrap | Laser maintenance can be costly |

| Automation Compatibility | Integrates easily with CNC or robotic arms | Skilled operators are often required |

| Thermal Influence | Controlled heat zone reduces warping | Potential small heat-affected zone at edges |

Laser technology continues to advance, broadening the range of thicknesses and material grades. While the process might cost more initially than older methods, many businesses recoup expenses through faster production and fewer errors.

Conclusion

So, What are the primary uses of laser cutting stainless steel? The laser application spectrum is multifaceted, including automotive components, industrial tools, kitchen utensils, surgical instruments, building components, aircraft parts, etc. In all cases, the resistant nature of stainless steel and the precision of lasers are an advantage to each industry. The result is cleaner cuts, less finishing work, and a product that stands up to rigorous demands.

To a reasonable degree, laser cutting stainless steel entails integrating the strength of metal with a contemporary adaptable cutting technique. Whether it’s an ongoing high-volume production of the same parts or a creative sculpting endeavor, laser cutting is the answer. With the assistance of appropriate software and skilled personnel, any design for the processed plates of stainless steel, from sturdy frames of cars to subtle decorations of restaurants, can be produced.

FAQs

- How thick can laser cutting stainless steel go?

Thickness limits vary by machine. Many industrial lasers handle up to half an inch or more. Check your specific laser’s power rating and settings.

- Does laser cutting warp stainless steel?

Not typically. The heat-affected zone is small, minimizing distortion. Thick or specialized alloys might see slight warping, but it’s far less than older cutting methods.

- Is it expensive compared to plasma cutting?

Laser systems cost more upfront, but they offer finer precision and less post-processing. For large runs or intricate designs, laser cutting can be more economical in the long term.