What is Prototype Manufacturing?

Building a manufacturing prototype means creating the first physical version of your product design. Not a sketch. Not a 3D rendering. An actual part you can hold, test, and break if needed.

Here’s what matters: prototypes catch problems before they become expensive. A design flaw found during prototyping might cost $500 to fix. That same flaw discovered after production tooling? Try $50,000 or more.

The rapid prototyping market hit $3.33 billion in 2024. That growth isn’t random. Companies finally understand that skipping prototype development doesn’t save time—it creates disasters.

Manufacturing prototype work answers three questions. Does this design actually work? Can we manufacture it without hemorrhaging money? Will customers use it the way we think they will?

Why Prototypes Matter More Than You Think

CAD software is impressive. It can simulate stress, analyze airflow, and predict how materials behave. But simulations have limits.

Take a medical device project from 2024. The CAD model looked perfect. Tolerance stack-up calculations checked out. Then the first prototype arrived. Assembly took three times longer than expected because two components—technically within tolerance—fought each other during installation. Nobody caught this until physical parts existed.

That’s not unusual. Manufacturing data from 2024 shows companies using thorough prototyping cut their development time by 15-20%. Seems counterintuitive, right? Spending more time on prototypes speeds things up. It does, because you’re fixing problems when they’re cheap to fix.

Investors know the difference between a pitch deck and a working prototype. One aerospace supplier spent $8,000 on a functional manufacturing prototype for a meeting with potential buyers. They closed a $2.3 million contract that afternoon. The prototype demonstrated capability in ways no presentation could match.

The global manufacturing sector generated $14.08 trillion in value-added production during 2025. Most of those products started as prototypes. The successful ones, anyway.

Different Prototypes Serve Different Purposes

Not every prototype needs to do everything. That’s a mistake engineers make constantly—trying to build one prototype that validates appearance, function, and manufacturing simultaneously. It doesn’t work well and costs too much.

Proof of concept models exist for one reason: proving the basic idea isn’t stupid. These run $100-$1,000 and take a week or two. A robotics company needed to verify a gripper mechanism would work. They 3D-printed a rough version for $300. It worked. That proof let them confidently invest in better prototypes.

Appearance models matter when aesthetics drive decisions. Consumer products live or die by how they look. An appearance prototype costs more than proof-of-concept but less than a functional model. Medical equipment manufacturers use these for regulatory approval photos before the device actually functions.

Functional prototypes perform like the real product. Materials might differ from production, but it works. Engineers can run durability tests, check ergonomics, and identify weak points. Budget $2,000-$20,000 depending on complexity. An industrial controls company spent $12,000 on functional prototypes that revealed their cooling system design was inadequate. Fixing that before production saved an estimated $200,000.

Engineering validation prototypes use production-intent materials and processes. If your final product uses glass-filled nylon, the engineering prototype should too. Testing with different materials gives you data that might not apply to the real thing.

Most products need 3-5 prototype iterations. The first one won’t be right. Accept that now and budget accordingly.

Reliable rapid prototype manufacturing delivering accurate models, fast iterations, and cost-effective solutions to help bring your product ideas to life quickly.

How Manufacturing Prototypes Actually Get Built

The process isn’t as straightforward as “send us your CAD file.” Good prototype manufacturers push back on designs that’ll cause problems.

Design work starts digitally. Modern CNC machines and 3D printers need precise CAD data. But here’s what engineering schools don’t emphasize enough: designing for manufacturability matters from day one. Beautiful CAD models mean nothing if they can’t be manufactured economically. Sharp internal corners? Can’t machine those. Undercuts everywhere? You just made molding expensive.

Material selection depends on what you’re testing. Early prototypes often use aluminum instead of steel because it machines faster and costs less. That’s fine for geometry verification. For strength testing? You need the real material. A defense contractor learned this the hard way—aluminum prototypes passed all tests, but steel production parts failed. The materials behaved differently under stress.

Manufacturing output reached $50.32 trillion globally in 2025, and material costs significantly impact both prototype and production budgets.

Manufacturing method choice involves tradeoffs. 3D printing is fast but materials are limited. CNC machining is slower but makes strong, precise parts. Injection molding needs expensive tooling but produces production-quality parts. There’s no universal “best” method.

Testing reveals what’s actually happening. Not what you hoped would happen. Test until things break. Then you know the limits. One automotive supplier tested their prototype to destruction and discovered the failure mode was graceful—the part bent rather than shattered. That information changed their safety documentation and made the product more attractive to buyers.

Manufacturing Technologies That Matter

Let’s talk about what these processes actually do, not marketing descriptions.

3D Printing Reality

Additive manufacturing builds parts layer by layer. Everyone knows this. What they don’t always realize: 3D printed parts aren’t as strong as machined ones from the same material. The layer lines create weak points.

That said, 3D printing excels at complex internal geometries. Machining can’t create certain shapes—tools can’t reach internal features. Printing can. An aerospace client needed cooling channels inside a component. Machining couldn’t do it. Printing could.

FDM works for quick functional checks. SLA gives you better surface finish. SLS makes decent nylon parts. Each has specific uses.

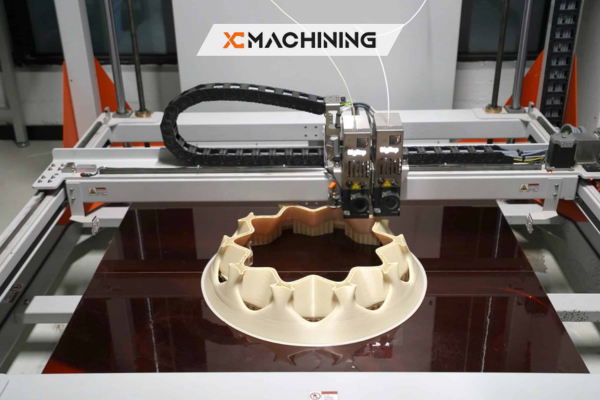

CNC Machining Gets Results

Machining removes material until you have the part you want. This creates strong parts with excellent surface finish and tight tolerances—we’re talking ±0.005 inches routinely, tighter if needed.

Materials aren’t limited. Steel, aluminum, titanium, brass, plastics, composites—if it’s machinable, we can work with it. A manufacturing prototype made on CNC equipment will perform more like the production version than one that’s 3D printed.

XC Machining handles precision CNC work daily. The difference between adequate prototypes and excellent ones often comes down to machining capability and experience.

Injection Molding for Volume

Molding requires tooling investment—aluminum molds start around $2,000, production steel molds can hit $100,000+. But molded parts are production parts. Same material, same process, same properties.

This makes sense when you need 100+ units or when testing must use production-identical parts. A consumer electronics company needed 200 prototypes for user testing. Molding was actually cheaper than machining that quantity.

What Prototypes Actually Cost

Budget discussions get uncomfortable because costs vary wildly based on design complexity.

Simple parts cost less. Obvious, but worth stating. A basic bracket might run $200-$500 machined. A complex housing with tight tolerances, multiple features, and difficult materials? $2,000-$10,000 easily.

Here’s reality from actual projects:

3D printing: $50-$5,000 per part. A medical device company spent $800 on printed prototypes for initial concept validation.

CNC machining: $200-$10,000 per part. Industrial equipment prototypes typically run $3,000-$7,000 for aluminum components.

Injection molding: $2,000-$100,000 in tooling, then $2-$50 per part. Consumer product client paid $15,000 for aluminum tooling, got 500 prototype parts at $8 each.

| Development Phase | Typical Method | Realistic Cost | Time Frame |

| Concept Check | 3D Printing | $50-$500 | 1-3 days |

| Function Test | CNC Machining | $500-$5,000 | 1-2 weeks |

| Engineering Validation | Machining/Tooling | $2,000-$20,000 | 2-6 weeks |

| Pre-Production | Injection Molding | $10,000-$100,000+ | 6-12 weeks |

Budget 2-5% of total development costs for prototyping. Companies that cheap out here usually pay later.

Electronic Prototype Manufacturing Challenges

Products with electronics complicate everything. You’re dealing with mechanical design, circuit design, firmware, and integration issues simultaneously.

PCB prototype turnaround has improved dramatically. Basic boards ship in 3-10 days now. But component availability causes delays. Chips with long lead times or allocation issues will stall your project regardless of how fast the PCB fabricates.

A commercial lighting company designed around a specific microcontroller. Six weeks into development, the chip went on allocation with 24-week lead times. The redesign cost three weeks and required new prototype boards. Could’ve been avoided by checking component availability first.

Testing electronic prototypes takes time. Functional tests are obvious—does it turn on? Does it perform the intended function? Then there’s compliance. FCC testing for emissions. Safety certifications. Thermal testing to ensure components don’t cook themselves. Power consumption measurements. All this needs to happen during prototype stages, not after you’ve committed to production.

Manufacturing automation continues improving in electronics. What that means practically: your prototype assembly process should resemble production assembly. Hand-soldering a prototype is fine for initial testing. But if production uses reflow, build some prototypes that way too. Assembly issues appear at that stage.

Plastic Prototype Manufacturing Options

Plastic parts dominate consumer products. Understanding plastic prototyping methods prevents expensive mistakes.

3D printing plastic prototypes is standard for concept validation. Quick, cheap, gets you something to hold. But printed parts don’t behave like molded parts. Layer lines create weak points. Material properties differ from production resins. CNC machining plastic makes stronger prototypes. Machining from solid plastic stock gives you real material properties. Surface finish is better. Tolerances are tighter. An industrial controls company machines ABS and polycarbonate prototypes because they need real strength data.

Urethane casting sits between printing and molding. You create a silicone mold from a master, then cast urethane parts. These look and feel more like production parts than printed versions. Cost and lead time fall between printing and injection molding.Injection molding plastic prototypes requires tooling but produces real parts. For products where material properties critically matter, this is the only valid test.

Material selection matters more than people realize. ABS, polycarbonate, and nylon have different strength, temperature resistance, and chemical compatibility. Test with the material you’ll actually use.The continuous casting market reached $3.5 billion in 2024. That’s mostly metal production, but it shows manufacturing’s scale and the investment in production technologies.

Trusted plastic prototype manufacturing near me offering precision modeling, rapid turnaround, and durable prototypes for product development and engineering projects.

Mistakes That Kill Prototype Projects

Some problems appear so consistently they’re worth calling out specifically.

Skipping prototypes entirely is the worst mistake. “Our CAD model is perfect, let’s go straight to production tooling.” Then they discover assembly problems, fit issues, or performance gaps. A $5,000 prototype could’ve prevented a $75,000 tooling disaster.

Testing with wrong materials gives you useless data. An automotive supplier tested plastic prototypes, then switched to glass-filled nylon for production. The production parts behaved completely differently—different coefficient of thermal expansion, different strength characteristics, different wear properties. All their test data was worthless.

Insufficient testing leaves problems hidden. Test to failure. Test edge cases. Test things you think are fine. Manufacturing data from 2024 indicates 86% of executives consider thorough prototype validation essential. They learned this lesson expensively.

Ignoring manufacturing constraints during design creates parts that are expensive or impossible to produce. One engineer designed a beautiful part with dozens of tight-tolerance features. Machining quotes came back at $8,000 per part. A slight redesign—loosening non-critical tolerances and simplifying some features—dropped cost to $1,200. Same functionality, 85% cost reduction.

Trying to test everything with one prototype doesn’t work well. Test appearance separately from function. Validate manufacturing feasibility with production-intent prototypes. Attempting to verify everything simultaneously usually means you verify nothing adequately.

Moving from Prototype to Production

This transition breaks more products than the prototype stage itself.

Design for manufacturing review catches expensive problems. A different set of eyes—preferably manufacturing engineers—examines the design for production issues. Can this be assembled efficiently? Are tolerances realistic for production volumes? Can we source these materials reliably? One medical device reduced part count from 17 to 9 during DFM review, cutting assembly time by 40%.

Production tooling costs real money. Injection molds run $5,000-$100,000+. Stamping dies, fixtures, jigs—it adds up quickly. This expense requires confidence your design is final. Late changes to production tooling cost even more.

Pilot production validates processes. Build 100-1,000 units using production tooling and methods. Problems always appear. Assembly takes longer than expected. A fixture doesn’t work quite right. A supplier’s material varies slightly from samples. Pilot runs catch these issues before you’re committed to tens of thousands of units.

Manufacturing capacity utilization hit 76.8% in 2024, showing strong production demand. That also means good manufacturers stay busy. Plan transitions carefully because you can’t always get immediate production capacity. Get precise and reliable prototype PCB manufacturing for rapid testing, circuit validation, and small-batch production. Perfect for startups, engineers, and product developers needing quick, accurate boards.

Choosing Manufacturing Partners

Partner selection matters more than price comparisons suggest.

Technical capability alignment comes first. Manufacturers specialize. A shop excellent at precision machining might not excel at plastic molding. Ask about specific experience with similar projects. Request samples. Talk to other clients.

Quality systems indicate reliability. ISO certifications aren’t everything, but they suggest documented processes and quality control. Industry-specific standards matter too—medical device manufacturers need different certifications than consumer product shops.

Communication responsiveness matters. Prototype projects involve quick iterations. Design changes happen. Questions arise. Partners who respond in hours rather than days make projects run smoother. That responsiveness adds value beyond manufacturing capability.

Intellectual property protection deserves attention. NDAs are standard. But also consider facility security, employee training on confidentiality, and the manufacturer’s track record. A leaked design before launch can destroy product advantage.

Price matters, obviously. But cheapest quotes sometimes come from manufacturers who don’t fully understand your requirements. Mid-range quotes from experienced shops often deliver better results.

Final Thoughts

Manufacturing prototype development determines whether products succeed or fail before mass production begins. The process seems expensive until you compare it to production failures.

Prototype work isn’t just building test parts. It’s learning what works, what doesn’t, and what needs changing. Each iteration brings clarity. Every test reveals information.

The prototyping industry keeps growing—20.49% annually—because companies recognize its value. Smart manufacturers invest in thorough prototype development. They test extensively. They iterate multiple times. They catch problems when fixing them costs hundreds instead of hundreds of thousands.

Trusted prototype manufacturing near me delivering precision parts, quick turnaround, and quality results.

Your first prototype won’t be perfect. Plan for that reality now and budget accordingly.

Frequently Asked Questions

What does prototype manufacturing actually involve?

Building physical versions of your design for testing before production. This validates functionality, checks manufacturability, and identifies problems that CAD analysis misses. Real-world testing reveals issues that only appear when you can hold and test actual parts.

What should I budget for a manufacturing prototype?

Simple 3D printed models start around $50-$500. Functional machined prototypes run $500-$5,000. Complex engineering prototypes with tooling can reach $10,000-$100,000+. Allocate 2-5% of your total product development budget to prototype work—it prevents much larger production expenses later.

How long does prototype development take?

3D printed parts: 1-3 days. CNC machined components: 1-2 weeks. Injection molded prototypes: 6-12 weeks including tooling time. Complete development with multiple iterations typically needs 2-6 months. Rush services exist but cost more and sometimes sacrifice quality.

What makes rapid prototyping different?

Speed and automation. Rapid prototyping uses CNC machining and 3D printing to produce parts in days instead of weeks. The rapid prototyping market hit $4.01 billion in 2025, growing at 20.49% annually as companies compete on faster development cycles.

When do I transition to production?

When prototypes consistently meet all requirements through multiple test cycles. When users validate the design works for real applications. When testing reveals no critical issues. When manufacturing can produce parts economically at your target volume. Rushing this transition costs more than taking time to validate properly.

References and Citations

- Precedence Research. (2024). “Rapid Prototyping Market Size, Share & Trends Analysis Report 2024-2034.” Market valuation: $3.33 billion in 2024, projected $21.47 billion by 2034. Retrieved from: https://www.precedenceresearch.com/rapid-prototyping-market

- Statista. (2025). “Manufacturing Market Worldwide – Forecast.” Global manufacturing output: $50.32 trillion in 2025, value added: $14.08 trillion. Retrieved from: https://www.statista.com/outlook/io/manufacturing/worldwide

- Deloitte Insights. (2024). “2024 Manufacturing Industry Outlook.” Survey data: 86% of manufacturing executives prioritize smart factory solutions for competitiveness. Retrieved from: https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook-2024.html

- Federal Reserve Board. (2024). “Industrial Production and Capacity Utilization – G.17.” Manufacturing capacity utilization: 76.8% in August 2024. Retrieved from: https://www.federalreserve.gov/releases/g17/current/

Data Horizon Research. (2024). “Continuous Casting Machines Market Size, Trends & Analysis Report 2024-2033.” Market size: $3.5 billion in 2024, projected 5.2% CAGR through 2033. Retrieved from: https://datahorizzonresearch.com/continous-casting-machines-market-25607