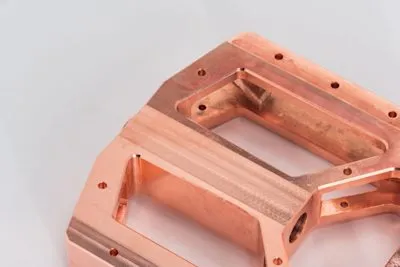

Copper C101, or Cu OFE, contains extremely low oxygen and impurity levels, giving it higher electrical and thermal conductivity than standard grades like C110. This purity makes it ideal for aerospace, medical, and semiconductor industries where performance reliability is critical.