Rapid prototyping depends on a combination of new manufacturing techniques, each appropriate to specialized design requirements, materials and proposed production. Here’s the most widespread technologies consist of:

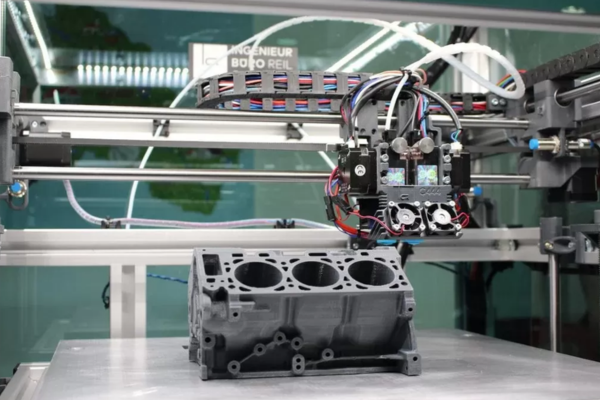

Additive Manufacturing (3D Printing)

This method builds parts in layers straight through CAD files which make complicated shapes and fast iteration possible.

- Fused Deposition Modeling (FDM): Parts are printed using melted thermoplastic filament and applied in layer-to-layer manner.

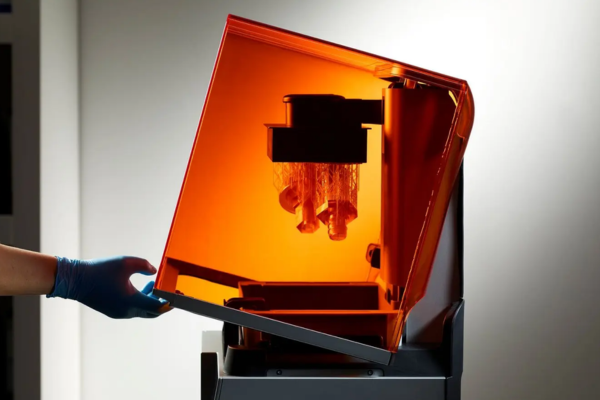

- Stereolithography (SLA): Virtually identical process to SLS except it uses a UV laser to cure a liquid resin into very detailed and smooth surface parts.

- Selective Laser Sintering (SLS): Uses a laser to bond blended nylon or different polymers into strong and functional end-use parts.

- Direct Metal Laser Sintering (DMLS): High powered laser is used to sinter fine metallic powder to create dense and complex metal components.

- Multi Jet Fusion (MJF): Uses less time to produce and high mechanical strength due to the application of fusing agents and heat to powder polymer.

Subtractive Manufacturing

CNC machines work to remove rather than add material to a solid block to produce the required shapes. This process is optimal when high tensile and critical tolerances with parts that can not be achieved with additive methods.

- CNC Milling: Cutting tools, rotating, are applied to rid a solid block of material, and this method is used to make complex shapes requiring the use of tight clearances.

- CNC Turning (Lathe): Rotates the workpiece on its axis as the tools that cut it take on the part of it. It is usually applied to cylindrical or symmetrical objects.

- Drilling Operations: Cuts fine holes / paths, and in many cases is combined with cutting on multi- axis machines.

- 5 axis CNC Machining: Allows cutting from multiple angles in a single setup, reducing production time and increasing precision.

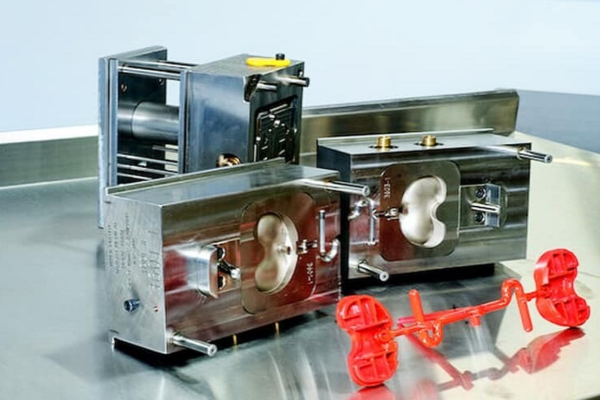

Molding

Due to the cycle of small batch production processes or parts which need particular materials, the techniques such as urethane casting and short-run injection molding would give quickness and reliability. The latter are usually applied after the design of a prototype is completed but prior to large-scale production.

- Injection Molding (Short-Run): Injection technique used to inject melted material into a mold to make small quantities of useful parts with superior finish.

- Compression Molding: Presses material into a mold that is heated, a common compression mold is a rubber or composite prototype.

- Vacuum Casting: Plems liquid resin into molds by use of vacuum pressure and is used on complex shapes and finer details.

- Silicone Molding: Is making molds out of silicone rubber, which are flexible, so that complex geometries can be copied, in a detailed way. Usually employed to cast resins, wax, or low-melting-point metals in the development of prototypes.

What Are the Benefits and Drawbacks of Rapid Prototyping?

With cutting-edge manufacturing processes, rapid prototyping has strong benefits as well as its own disadvantages. The realization of both sides assists businesses in determining the appropriate moment to efficiently exploit it.

Here’re some Perks of Rapid Prototyping:

Flexibility

The rapid prototyping enables rapid exploration of a number of design iterations within a relatively short period of time that can aid the designers and engineers. As an example, a product team is able to develop three versions of a component, test them in terms of performance and optimize the most suitable one without making a clean sheet. Such repeated process brings innovation and the chances of failure of launching a product that does not meet the needs of the market is minimised.

Speed

Rapid prototyping is able to reduce development cycles by half or greater, by avoiding costly conventional tooling and long cycle setup costs. In rapid moving industries such as consumer electronics, such velocity may spell the difference between setting or following the pace. 3D printing of a functional prototype only takes 24 hours and not weeks, as it is the case with traditional machining.

Cost Savings

The traditional prototyping techniques usually require unique molds or tooling that may lead to thousands of dollars. These costs are reduced or altogether avoided due to the use of rapid prototyping at early stages of design which saves major investment to tune 30-60 percent of the initial cost. It proves to be particularly useful to start up and small enterprises with limited budgets.

Reduced Waste

Additive manufacturing of a part happens layer after layer, utilizing only the amount of material required per design. This makes it far less wasteful than subtractive manufacturing by producing less scrap thus saving material cost and increasing sustainability. Switching to rapid prototyping back when doing early builds has reported up to 80 percent waste reduction in some companies.

Here’re some Drawbacks of Rapid Prototyping:

Material Limitations

Rapid prototyping can work with an ever-increasing range of plastics, resins, and even metals, but the set is still more limited compared with conventional manufacturing. It can restrict the accuracy of the functional testing because some materials do not reflect the strength, flexibility, or heat resistance of final production-grade materials.

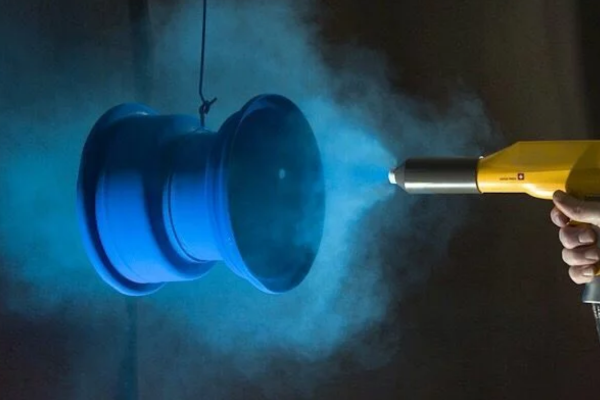

Surface Finish Issues

Layer-by-layer production may produce visible striations or a scratched surface on prototypes, especially on FDM printing. To obtain a polished, market ready surface, extra finishing steps like sanding, coating, or CNC machining may be necessary after which other time and cost may be involved.

Scalability Constraints

Rapid prototyping is ideal with the one off parts or small quantities but not necessarily economical in higher volumes mass production. This would be the case whereby a single prototype could be printed in hours yet thousands of them would confer the advantage of traditional injection molding or casting to produce them speedily and in terms of unit cost effectiveness.