Explore advanced laser technologies that harness light with remarkable precision, transforming diverse materials into clean, accurate components while maximizing efficiency, detail, and performance for today’s demanding production environments.

CO₂ Laser Cutting

Utilizes a gas mixture mainly carbon dioxide as the lasing agent CO₂ lasers are very effective to both cut and cut-through non-metals (such as wood, plastics, paper, and some fabrics) and thin metals. They give smooth edges and are popularly used in decorative and sign applications.

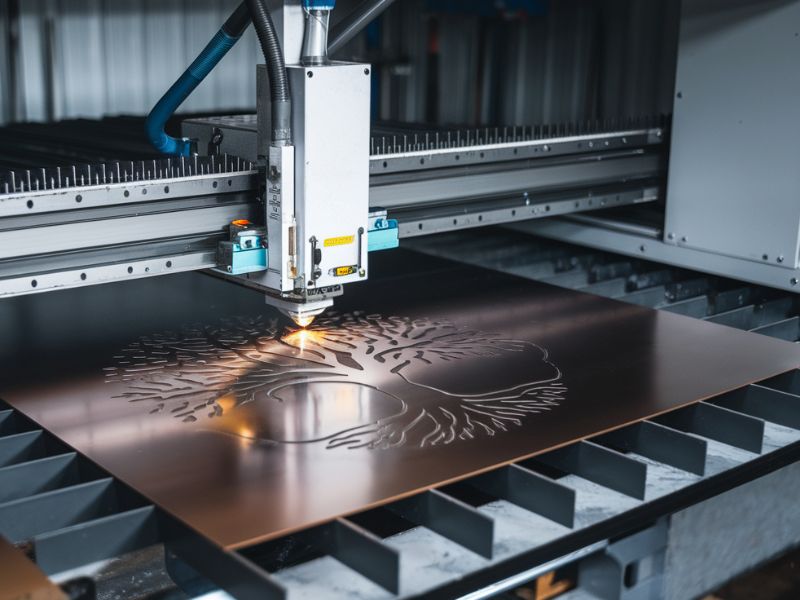

Fiber Laser Cutting

Uses specialised optical fibre that has rare-earth elements impregnated in it so as to generate a high-power laser. They are energy-saving, need a lower maintenance rate, and know best how to cut such metals as stainless steel, aluminum, brass, and copper. Fiber lasers have higher cutting speeds when used on thin materials than the CO 2, increasing efficiency and throughput.

Crystal Laser Cutting (Nd:YAG / Nd:YVO)

Uses solid state crystal as a lasing medium e.g. neodymium-doped Yttrium aluminum garnet (Nd:YAG) or neodymium-doped Yttrium ortho-vanadate (Nd:YVO₄). These lasers are high-intensity lasers and are preferably used in situations that demand extremely fine resolution or marked engraving on metals and ceramics.

Hybrid Laser Systems

Combine laser with other cutting or positioning tools to get the best of speed, accuracy and the ability to cut various forms of material. This might require use of a water jet or mechanical.

What Are The Challenges in Laser Cutting?

Laser cutting has advantages of high precision, fast processing speed and flexibility, but some factors need to be controlled. These factors can be understood, and it will mean superior process management and more quality outputs.

Material Reflectivity

Metals with high reflectivity, such as copper, brass or performance grades of aluminum alloys, can reflect the laser beam back at machine optical components. This does not only diminish cutting efficiency but poses a threat of damaging costly optical components. This is usually overcome by special laser wavelengths or surface treatments.

Heat-Affected Zones (HAZ)

The effects of the high heat generated in the course of laser cutting may cause changes in the microstructure of the materials in the cutting zone of the cutting room. This can cause warpage, discolouration or hairline cracks especially in thin or thermally sensitive materials. There are also undesirable effects which can be reduced by careful settings of power and cutting speed.

Edge Quality and Burr Formation

When the cutting parameters are not adequately optimized it is possible that edges will become rough or form burrs which then require secondary finishing operations. A sharp and consistent cut edge is affected by factors like focal point setting, gas pressure and material material thickness.

Thickness Limitations

Laser cutting allows a broad range of material thicknesses, plates that are very thick may need to be cut at low cutting speeds and/or require multiple passes to complete the cut, which can reduce productivity and contribute to distortion due to the heating effect of the laser.

Operational and Maintenance Costs

High-end laser cutting equipment, especially the systems with higher-tech fiber or CO₂ are expensive. Upkeep, provisions and skilled labour contribute to the total expendable cost.