Overmolding is a groundbreaking manufacturing technique where one plastic material is molded over another to create a single, unified product. This process not only enhances functionality and durability but also achieves a sleek, visually appealing design.

At XC Machining, we specialize in providing advanced overmolding solutions tailored to meet the unique needs of various industries. By leveraging this innovative technology, we deliver products that seamlessly combine strength with precision, making us a trusted partner for industries like automotive, energy, electronics, medical devices, and consumer goods.

The Unique Perks of Overmolding

Superior Performance Across Applications

Overmolding offers unparalleled advantages by combining materials with distinct properties, enabling the creation of components with enhanced durability, impact resistance, and thermal performance. Here’s how it benefits various industries:

- Automotive: Overmolded parts production improve the durability of interior and exterior components like handles, knobs, and electronic housings, ensuring they withstand harsh conditions.

- Electronics: Enhanced electrical conductivity and insulation properties make overmolds indispensable for connectors, switches, and protective enclosures.

- Medical Devices: Provides improved ergonomics and safety for instruments and drug delivery systems, ensuring precise and comfortable use.

- Energy Sector: Overmolded components exhibit superior thermal performance, making them ideal for high-temperature environments.

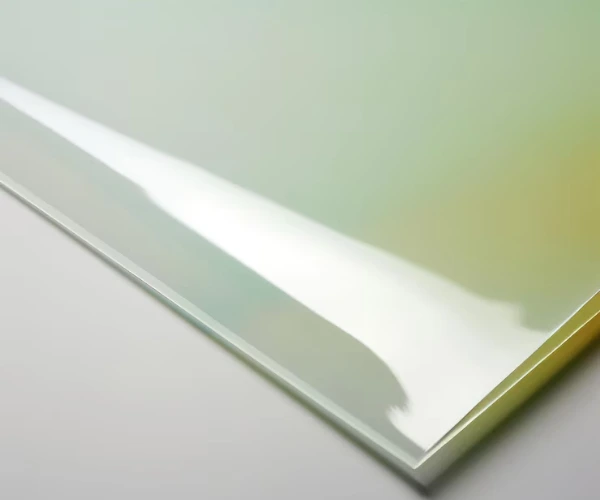

Enhanced Aesthetic Appeal

In addition to functionality, overmolding allows for the customization of colors, textures, and finishes to create visually striking designs. Whether it’s a sleek consumer gadget or a professional-grade medical instrument, overmolding offers:

- Smooth material transitions for a cohesive design.

- Customization options that align with brand identity.

- Improved end-user satisfaction through an enhanced visual and tactile experience.

Cost-Efficiency in Manufacturing

By combining multiple components into a single part during the molding process, overmolding reduces:

- Assembly Costs: Fewer components mean reduced labor and time.

- Production Time: Accelerated manufacturing cycles allow for large-scale production without compromising quality.

- Material Waste: Optimized processes reduce material usage, lowering costs further.

These efficiencies make overmolding a highly cost-effective solution for industries that demand large-scale production, such as automotive, consumer goods, and electronics.

Enhanced Safety and User-Centric Design

Prioritizing Safety

Overmolding allows manufacturers to incorporate features such as:

- Non-Slip Grips: Essential for automotive and consumer goods.

- Shock Absorption: Reduces the impact on sensitive components, especially in medical and industrial applications.

- Ergonomic Features: Soft, rubber-like materials improve grip and reduce user fatigue, enhancing safety and comfort across industries.

User-Friendly Innovations

A superior user experience is at the heart of overmolding. By integrating ergonomic grips, soft-touch surfaces, and aesthetically pleasing designs, overmolded products stand out in terms of comfort and usability. This approach is particularly beneficial in:

- Medical Devices: Ensures precision and ease of use.

- Consumer Goods: Enhances overall satisfaction with visually appealing and comfortable products.

- Electronics: Provides robust, user-friendly interfaces for high-tech gadgets.

Why Choose XC Machining for Overmolding?

At XC Machining, we combine cutting-edge technology with years of expertise to deliver overmolding solutions that exceed expectations. Here’s why partnering with us makes a difference:

- Advanced Capabilities: Our state-of-the-art facilities and innovative processes ensure precision and quality in every component.

- Industry Expertise: With extensive experience in sectors like automotive, medical, and electronics, we understand the unique challenges of each industry.

- Material Versatility: We work with a wide range of materials to meet diverse design and performance requirements.

- Commitment to Quality: Every product undergoes rigorous quality control to ensure it meets the highest standards of durability and functionality.

Partner with XC Machining Today

Choosing XC Machining for your overmolding needs means more than just manufacturing parts; it means creating products that combine durability, functionality, and aesthetic appeal. Whether you’re in the automotive, medical, electronics, or consumer goods industry, our tailored solutions ensure your products stand out in the market.

Contact us today to learn how our overmolding expertise can transform your manufacturing process and bring your vision to life.