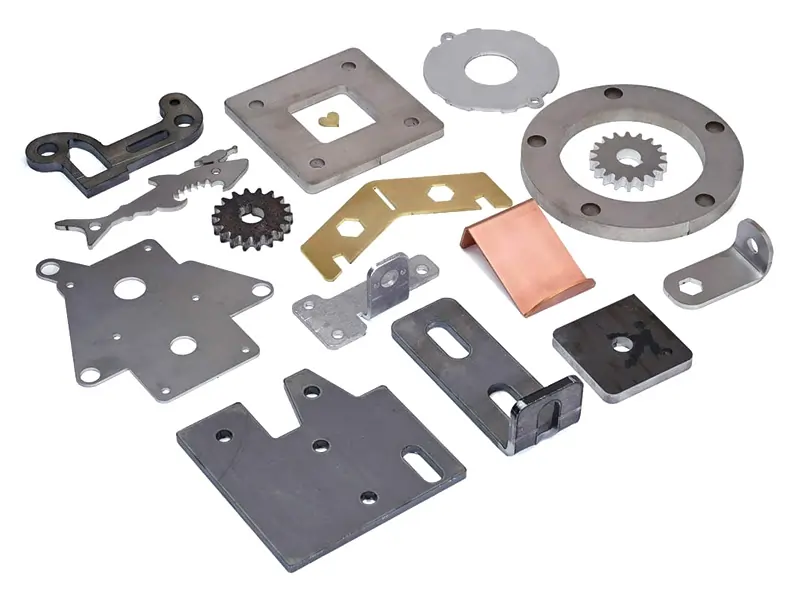

To accurately cut the sheet metal in a fast and efficient manner that leaves little or no wastage, XC Machining uses a precise CNC driven process. It involves making the appropriate material selection, coming up with programming the sophisticated machines, and implementing the precise mainframe response of the cutting.

Here’s a step by step listing of how we turn raw sheet metal into slightly cut down production ready parts.

1. Material Selection

Every great part begins with the selection of the appropriate sheet metal. XC Machining uses many different metals including, depending on the application:

- Aluminum: It is very light in weight and resistant to corrosion and is best used in aerospace and electronics.

- Stainless steel: This is favored because of its strength and the resistance to corrosion; it is applied in medical, food processing and marine markets.

- Mild Steel: Low cost, and easy to weld or to machine; it is commonly used in construction and automotive.

- Titanium: This metal is very strong and lightweight; good to be used in aerospace and high performance gear.

Each of the materials is checked in terms of thickness, tensile strength, weight, heat resistance, and the surface finish requirements and is found to fulfill the project requirements of the client.

2. CAD Design

Once the material is selected, our engineering team develops a CAD (Computer-Aided Design) model that acts as a digital blueprint for the sheet cutting operation. The design includes:

- Overall dimensions and tolerances

- Hole placements, notches, and intricate geometries

- Bend lines or reference markings for future operations

- Nesting strategies to optimize sheet usage and reduce waste

This stage ensures that all details are digitally validated before any material is touched, minimizing rework and ensuring first-time-right production.

3. CAM Programming

Once CAD model is done, the program is submitted to CAM (Computer Aided Manufacturing) program. This device converts the design to G-code, a numerical control programming language which directs the CNC machine as to:

- Tool paths and entry/exit points

- Cutting sequence and direction

- Spindle speed and feed rate

- Tool type, nozzle type (laser, plasma, waterjet), and power settings

4. CNC Sheet Cutting Operation

Actual cutting takes place on our CNC sheet cutting machines but it is done using single or a combination of the below methods as dictated by the needs of the job:

- Laser Cutting is a highly precise process where a focused beam of laser will cut clean and relatively intricate shapes with little or no material deflection.

- Plasma cutting is an effective and quick process , which involves slicing of thick and conductive metals such as steel and aluminum with the help of a hot plasma arc.

- Waterjet Cutting is a cold cutting technique that employs a high pressure stream of water (mixed with abrasive grains when used in its harshest form) to cut accurately without heating heat sensitive or otherwise thick materials such as absorptive fibers and industrial metals.

- CNC Punching is a quick process of cutting sheet metal using a combination of a CNC controlled punch and die to create slots, holes and shapes that can be replicated many times over, at high volumes and repetitive batch sequences.

The chosen process will be set to speed, tolerance and edge quality where the end result is exact to engineering requirements.

5. Deburring and Surface Finishing

Sharp edges, slag or micro-burrs are encountered after cutting, in opposing raw sheet parts. In order to have safe handling, and high quality end product we conduct:

Deburring cleans up sharp edges and burrs that are formed during the cutting process and leaves smooth, safe and accurate sheet metal components.

- Cutting produces rough surfaces leaving an uneven metal sheet, sanding or Grinding smooths these surfaces and erases any imperfection on the metal sheet after the cutting.

- Polishing adds shine to the surface which leaves the sheet metal with a clean, reflective look.

- Anodizing-/Powder Coating is a process to add corrosion resistant decorative and protective coating.

- Finishing procedures do not solely aim at improving the aesthetic and tactile appearance but also condition the parts to either welding, bending or assembly.

Quality Control During the process

XC Machining has applied stringent quality standards in its inspection of the initial raw materials to their final inspection concerning dimensional checks. Validation of each part is accomplished with such tools as:

- CMMs (Coordinate Measuring Machines)

- Laser micrometers

- Visual inspections and edge analysis

What Are The Challenges in Sheet Cutting ?

Sheet cutting challenges include distortion, burrs, and accuracy issues that can impact part quality.

Warping of material and distortion

The thermal stress can warp thin cuts in metal sheets where high temperatures are involved such as in laser, or plasma cutting processes. This causes problems in dimension accuracy and possibly in assembly. To avert this, it is important to control the entry of heat and employ fixtures.

Edge Quality and Burr Formation

There are bad tool settings or sharp edges that can result because of bad tools or old ones that are worn out. The flaws are further deburred or polished which makes the production more time-consuming and expensive. Aided by precision tools and parameter tuning, this can be done.

Inconsistent Thickness and Material Hardness

The difference in the thickness of the sheets or even hardness may interfere with the consistency of the cuts. This particularly poses problems where automated systems are employed where settings are set in stone. This is reduced through real time monitoring and standardization of materials.

Tool Wear and Maintenance

Blades, nozzles, or laser optics are cutting tools that deteriorate with time and thus it affects the quality and precision of cutting. The degradation of the tools without proper schedule of maintenance may lead to the delays of the production or reworking with a subsequent high cost. Predictive maintenance is becoming a necessity.

Material Waste and Nesting Inefficiency

The poor nesting and part layout on sheet may incur too much wastage of material. This increases the costs and reduces the profitability due to poor nesting strategies. Implementation of intelligent CAD/CAM software is able to have drastic effects on sheet utilization.