Are you struggling to keep up with the rapid changes in precision sheet metal fabrication? Perhaps you’ve heard about new techniques, but you’re not sure which ones matter most for your business. If that sounds familiar, you’re in good company. I’ve spoken to several friends who work in manufacturing, and they all mention how tough it is to stay current and competitive.

If you want a quick solution to improve precision sheet metal fabrication, focus on:

- High-accuracy cutting methods

- Automated welding systems

- Advanced 3D printing integration

- AI-driven product design

- Hybrid forming approaches

In this post, we’ll explore how these five innovations are changing the game for precision sheet metal fabrication. We’ll also look at some interesting overlaps with silicone molding, compare old and new methods, and discuss trends for the future.

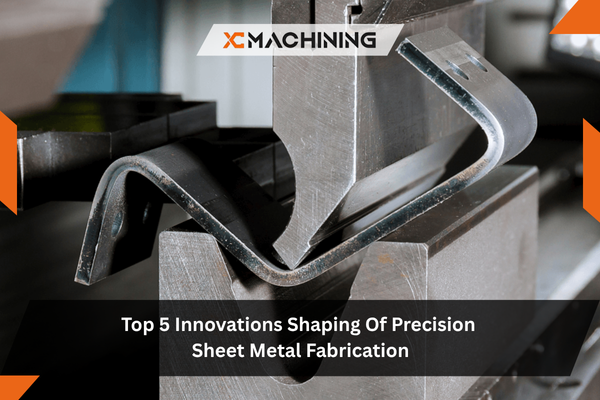

Precision Sheet Metal Fabrication: Why It Matters

Precision is the lifeblood of modern manufacturing. In precision sheet metal fabrication, a tiny miscalculation can lead to wasted materials and costly do-overs. Every component must fit perfectly into a larger system, whether it’s an airplane wing, a medical device casing, or a consumer electronics enclosure.

Faster Production Cycles

Speed is crucial in precision sheet metal fabrication. By cutting and shaping materials with the utmost accuracy, companies minimize the need for multiple adjustments. This boosts production speed, helping you finish projects sooner and gain a competitive edge in the marketplace.

Lower Material Waste

Waste hurts your wallet and the environment. When precision sheet metal fabrication is done well, each cut is clean and exact. That means less scrap metal to toss out. Reducing waste also slashes costs, which can then be passed along as savings to customers.

Greater Design Freedom

High-level precision opens new doors for imaginative designs. With improved tooling and digital modeling, precision sheet metal fabrication can bring even the most intricate concepts to life. As complexity grows, precision ensures every bend, hole, and joint aligns perfectly with the original design vision.

Laser Cutting Advancements

Here’s the paragraph with the keyword sheet metal fabrication tools added just once:

Laser cutting has been around for years, but recent advancements make it more accurate and energy-efficient than ever. In precision sheet metal fabrication tools, these cutting-edge lasers can handle complex geometries without slowing down.

Quick Tip: Look for machines with adaptive beam control. They adjust the laser’s intensity in real-time, ensuring clean edges on materials of varying thicknesses.

Modern laser cutting also reduces thermal distortion. Excessive heat can warp materials, but these advanced tools help maintain the integrity of the cut.

Let me know if you’d like any more adjustments! Laser cutting has been around for years, but recent advancements make it more accurate and energy-efficient . By focusing energy precisely, lasers now keep metal cooler, preserving the integrity of each part. This is especially useful in industries like aerospace, where precision can be a matter of safety.

Automated Robotic Welding

Welding can be tricky, especially when you’re dealing with tight deadlines or mass production. That’s why automated robotic welding has become a big deal in precision sheet metal fabrication. Robots ensure consistent welds at a pace no human can match.

A bonus of robotic welding is worker safety. Welding fumes and sparks are dangerous, but robots never need a coffee break or safety goggles. This frees up your human team to focus on tasks that require creativity or detailed problem-solving.

- Info: Automated systems also track performance metrics. That data helps you adjust welding parameters on the fly and maintain top quality.

3D Printing In Metal Fabrication

3D printing isn’t just for plastic prototypes anymore. Engineers are now exploring metal 3D printing for precision sheet metal fabrication. While it might sound strange to “print” metal parts, the technology has taken huge strides in recent years.

One advantage is reduced tooling. Traditional fabrication often requires multiple setup stages. With metal 3D printing, designs go straight from digital models to physical parts, cutting out intermediate steps. For small batches or unique shapes, this can save both time and money.

- Fact: According to ASTM International, additive manufacturing standards for metal are evolving quickly, helping companies ensure parts meet rigorous industry specifications.

AI-Driven Design And Prototyping

Artificial intelligence is making life easier for designers, especially in precision sheet metal fabrication. AI can optimize layouts and suggest the most efficient cutting patterns. This speeds up the design phase and cuts back on trial and error.

Imagine feeding your design specs into a specialized program. In seconds, it generates multiple versions, each with improved weight distribution and minimized stress points. Once you approve a model, you can move to production with confidence, knowing that an AI has already stress-tested your concept.

- Suggestion: Always double-check AI-generated models. While AI is powerful, it still needs human oversight to catch any issues that algorithms might miss.

Hybrid Forming Techniques

In precision sheet metal fabrication, forming is where flat metal transforms into a 3D structure. Hybrid methods combine processes like stamping, bending, and even incremental forming. By blending different approaches, manufacturers get the best of each technique, improving speed and accuracy.

Hybrid forming can also incorporate heating elements or ultrasonic vibrations to reduce metal stress. This allows more precise bends and curves without cracking. The result? Complex parts that are still within tight tolerance limits, even after repeated shaping steps.

- Danger: Always monitor temperature and stress levels in hybrid form. Overheating or excessive force can ruin the metal’s structure, leading to part failures down the line.

Key Industries Using Silicone Molding

You might be wondering what silicone molding has to do with precision sheet metal fabrication. Interestingly, many industries that rely on silicone molding also need metal components that meet strict tolerances. Here’s a quick overview of key sectors where silicone parts and sheet metal parts often go hand-in-hand.

Medical Devices

Silicone’s biocompatibility is perfect for implants, seals, and tube connectors. Hospitals also need metallic enclosures for diagnostic machines.

Automotive

Silicone is used for gaskets and seals due to its heat resistance. Vehicles also contain countless sheet metal frames and brackets that demand precision.

Electronics

Silicone protects circuits from moisture, while metal housings keep devices safe from physical damage. In smartphones, tablets, and wearables, both materials are crucial.

Aerospace

Silicone’s durability helps with sealing components that face extreme temperatures. Meanwhile, aircraft panels and support structures rely heavily on precision sheet metal fabrication.

Consumer Goods

Items like kitchen utensils use silicone for heat resistance. If those products have metal elements—like handles or internal parts—they need precise metal shaping to fit perfectly with the silicone sections.

Warnings: Always confirm material compatibility. Some chemicals in metal finishing can damage silicone, so coordinate both processes carefully.

Comparing Old Vs. New Methods

Let’s put traditional approaches side by side with modern techniques to see why precision sheet metal fabrication is evolving so quickly. This comparison gives you a clear snapshot of how far we’ve come—and why it matters.

| Method | Traditional Approach | Modern Innovation |

|---|---|---|

| Cutting | Manual or mechanical shears | High-powered laser cutting and water |

| Welding | Handheld welding with limited automation | Robotic arms ensure consistency and speed |

| Forming | Basic stamping or bending | Hybrid forming with temperature control and ultrasonic methods |

| Prototyping | Physical trial-and-error | AI simulations and rapid 3D printing |

| Material Efficiency | Higher waste due to guesswork | Optimized designs reduce scrap metal |

| Integration With Silicone Parts | Minimal attention to sealing edges | Precise fits ensure tight seals for silicone-metal enclosures |

Each row shows how older methods have been upgraded or replaced by cutting-edge techniques. The result is a more efficient, cost-effective, and precise production line—something every manufacturer aims for in precision sheet metal fabrication.

Trends To Watch For Future Growth

What’s next in precision sheet metal fabrication? Let’s talk about some trends on the horizon. As industries grow more connected, expect more data-driven insights to optimize the entire production chain.

Real-Time Sensors

Factories may implement IoT sensors on every machine, flagging issues before they become big problems. This proactive approach keeps downtime to a minimum.

Eco-Friendly Metal Alloys

Researchers are developing alloys that are lighter and stronger, reducing energy usage in transport and production.

Machine Learning Diagnostics

Advanced systems might predict which parts will fail or degrade first, giving you time to order spares or change your process.

Unified Supply Chains

Manufacturers might share digital blueprints to speed up collaboration across international borders.

Increased Silicone Integration

Expect more products that blend silicone and metal components, especially in automotive, medical, and consumer goods.

Conclusion

Keeping up with rapid changes in precision sheet metal fabrication can feel daunting. From laser cutting to AI-driven design, each innovation promises greater accuracy, faster turnaround, and lower costs. These advancements allow manufacturers to meet evolving demands, whether you’re building electronic devices, cars, or even parts that integrate silicone components for specialized uses.

In short, precision sheet metal fabrication is racing into the future with powerful new tools and processes. If you’ve been on the fence about adopting new technology, now is the perfect time to dive in. With improved efficiency and reliability, your final products will stand out in an increasingly competitive marketplace.

FAQs

- How does precision sheet metal fabrication reduce waste?

By ensuring each cut or bend is highly accurate, fewer scraps go to the trash. This boosts efficiency and saves money.

- Are robots replacing human welders entirely?

Not exactly. Robots handle repetitive tasks in precision sheet metal fabrication, but humans still program and oversee them. Skilled welders are needed for complex custom jobs.

- Can I use metal 3D printing for mass production?

It’s more common for small batches or custom parts. For huge volumes, other methods might be more cost-effective, but 3D printing is catching up fast.

- How do silicone components interact with metal parts?

They often form tight seals or coverings. Many industries rely on silicone’s flexibility and metal’s durability for products like medical devices and consumer goods.

- Why is AI design so valuable?

AI can instantly explore multiple design options, optimizing materials and shapes without the usual trial-and-error, saving time and resources in precision sheet metal fabrication.