What This Guide Covers

Injection molding applications span virtually every industry in modern manufacturing, from the smartphone in your pocket to the dashboard in your car. Understanding where and why injection molding dominates helps engineers, product designers, and business owners make informed manufacturing decisions.

In this comprehensive guide:

- The top 10 injection molding applications across industries

- Why injection molding works best for each application

- Material considerations and process variations

- Real-world examples from actual manufacturing projects

- Future trends in injection molding applications

Whether you’re exploring plastic injection molding applications for consumer products or evaluating metal injection molding applications for precision components, this guide provides practical insights from years of hands-on manufacturing experience.

Why Injection Molding Dominates Modern Manufacturing

After 14 years working with injection molding across automotive, medical, consumer electronics, and industrial sectors, I’ve seen firsthand why this process has become the manufacturing method of choice for millions of products. The versatility of injection molding applications continues to expand as materials and technologies advance.

Last year, a startup founder asked me why they couldn’t just 3D print their consumer product instead of investing in injection molding tooling. I showed them the math: 3D printing cost $8.50 per unit at their target volume of 50,000 units annually. Injection molding brought that cost down to $1.20 per unit after the initial tooling investment. Over two years, injection molding saved them $364,000.

But cost isn’t the only reason injection molding applications have grown so dramatically. The process delivers:

- High precision and repeatability – Parts match within 0.001″ across millions of cycles

- Complex geometries – Features impossible with other manufacturing methods

- Material versatility – Thousands of material options from commodity plastics to advanced ceramics

- Production efficiency – Cycle times measured in seconds, not minutes or hours

- Excellent surface finish – Class A cosmetic surfaces directly from the mold

- Design flexibility – Integration of multiple features, colors, and materials

Understanding Different Types of Injection Molding

Before diving into specific applications of injection molding, it’s important to understand the various process types:

Process Type Materials Typical Applications Key Advantage

Plastic Injection Molding Thermoplastics (ABS, PC, PP, Nylon) Consumer products, automotive, packaging Most versatile, lowest cost

Metal Injection Molding (MIM) Stainless steel, titanium, tungsten Medical implants, firearms, watches Complex metal geometries

Ceramic Injection Molding (CIM) Alumina, zirconia, silicon nitride Electronics, cutting tools, medical High temperature, wear resistance

Reaction Injection Molding (RIM) Polyurethanes, epoxies Large automotive parts, enclosures Large parts, low pressure

Liquid Silicone Rubber (LSR) Medical-grade silicones Medical devices, infant products Biocompatibility, flexibility

PVC Injection Molding Polyvinyl chloride compounds Pipe fittings, electrical, medical Chemical resistance, durability

Each process variation opens new injection molding applications that leverage specific material properties.

Top 10 Injection Molding Applications

Based on production volume, economic impact, and technological significance, here are the top 10 injection molding applications shaping modern manufacturing:

1. Automotive Components (Interior and Exterior)

Why injection molding dominates: The automotive industry represents the largest consumer of plastic injection molding applications globally, with each vehicle containing 200+ molded plastic parts.

Common components:

- Dashboard assemblies and instrument panels

- Door panels and interior trim

- Center consoles and cup holders

- Bumpers and exterior trim pieces

- Lighting housings and lenses

- HVAC ducts and vents

- Under-hood components (reservoirs, covers)

Real-world example: I worked on a dashboard project that consolidated 12 separate parts into one injection-molded component using two-shot molding. This reduced assembly time by 40% and eliminated 11 potential failure points.

Materials used:

- Polypropylene (PP) – Interior trim, bumpers

- ABS – Instrument panels, interior components

- PC/ABS blends – High-impact areas

- Nylon (PA) – Under-hood, structural parts

- TPE – Soft-touch surfaces

Why it works: Injection molding delivers the complex geometries, tight tolerances, and aesthetic surfaces automotive applications demand while meeting aggressive cost targets at high volumes.

2. Consumer Electronics and Device Housings

Why injection molding dominates: Electronics manufacturers need precise, lightweight housings with integrated features like snap fits, screw bosses, and cable management—exactly what injection molding delivers.

Common components:

- Smartphone and tablet cases

- Laptop housings and keyboards

- Television frames and bezels

- Remote control housings

- Computer mice and peripherals

- Gaming console shells

- Smart home device enclosures

Real-world example: For a major electronics brand, we developed a laptop housing using glass-filled nylon that reduced weight by 35% versus the previous aluminum design while maintaining structural integrity and improving thermal management.

Materials used:

- Polycarbonate (PC) – High impact resistance

- ABS – Good balance of properties

- PC/ABS – Premium appearance with toughness

- Glass-filled nylons – Structural applications

- Flame-retardant grades – Safety requirements

Industry significance: Consumer electronics represents one of the fastest-growing plastic injection molding applications, with estimated global production exceeding 5 billion units annually.

3. Medical Devices and Healthcare Products

Why injection molding dominates: Healthcare demands biocompatible materials, sterilization compatibility, and FDA-compliant manufacturing—all achievable through controlled injection molding processes.

Common components:

- Syringes and IV components

- Surgical instruments and handles

- Diagnostic device housings

- Drug delivery systems

- Implantable device components (via metal injection molding applications)

- Laboratory consumables

- Respiratory devices

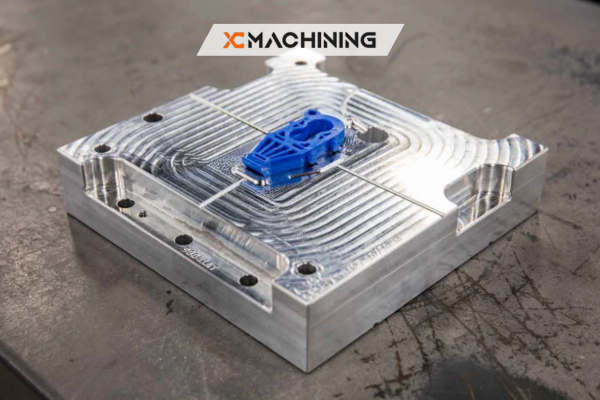

Real-world example: I consulted on an FDA Class II medical device where we transitioned from machined components to metal injection molding applications. This reduced per-part cost from $28 to $4.50 while improving consistency and eliminating secondary operations.

Materials used:

- Medical-grade polypropylene

- Polycarbonate (biocompatible grades)

- PEEK (high-performance implants)

- Liquid silicone rubber (LSR)

- Stainless steel (MIM for implants)

- Medical-grade PVC injection molding applications

Critical requirements: Clean room manufacturing, lot traceability, biocompatibility testing, and sterilization validation make medical applications among the most demanding injection molding applications.

4. Packaging and Container Production

Why injection molding dominates: The packaging industry requires billions of identical containers, caps, and closures—perfect for high-cavity injection molding’s efficiency.

Common components:

- Bottle caps and closures

- Food containers and tubs

- Cosmetic packaging

- Pharmaceutical bottles

- Rigid packaging components

- Dispensing pumps and sprayers

Real-world example: A beverage cap project I managed ran 32-cavity molds producing 2,800 caps per hour per machine. At this scale, per-part cost dropped to $0.018, making injection molding the only economically viable manufacturing method.

Materials used:

- Polypropylene (PP) – Most common for caps and containers

- High-density polyethylene (HDPE) – Bottles and jars

- PET – Preforms for blow molding

- PS (Polystyrene) – Rigid packaging

Economic scale: Packaging represents the highest volume of all plastic injection molding applications, with trillions of units produced globally each year.

5. Toys and Recreational Products

Why injection molding dominates: Toys require colorful, durable, safe materials that can be produced in high volumes at low cost—injection molding’s specialty.

Common components:

- Action figures and dolls

- Building blocks and construction toys

- Game pieces and components

- Outdoor sports equipment

- Ride-on toys and vehicles

- Educational toys

- Model kits

Real-world example: For a major toy brand, we designed a 16-cavity family mold producing complete toy car assemblies (body, wheels, base) in matched colors. This approach reduced assembly operations by 60% and ensured perfect color matching across all components.

Materials used:

- ABS – Most common toy plastic (LEGO uses ABS)

- Polypropylene – Flexible, durable toys

- TPE – Soft-touch areas and grips

- Polycarbonate – Transparent components

Safety requirements: Toy applications of injection molding must meet strict safety standards including ASTM F963, EN 71, and international toy safety regulations.

6. Industrial and Manufacturing Components

Why injection molding dominates: Industrial applications need durable, chemical-resistant parts that can withstand demanding environments while remaining cost-effective.

Common components:

- Gears and mechanical components

- Housings for industrial equipment

- Handles and control knobs

- Protective guards and covers

- Cable management systems

- Fasteners and mounting hardware

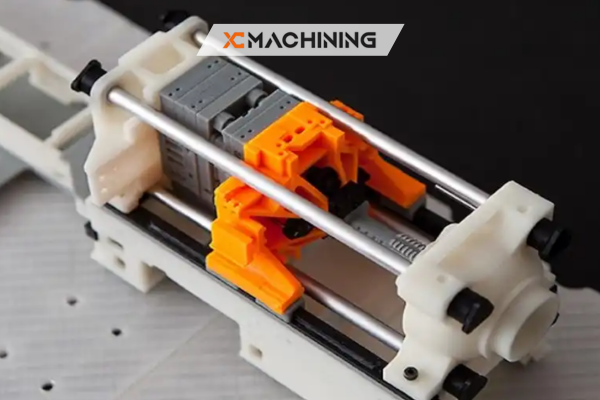

- Tooling and fixtures

Real-world example: Using glass-filled nylon, we replaced machined metal gears in a material handling system. The injection-molded gears cost 85% less, reduced noise by 40%, required no lubrication, and lasted longer due to superior wear properties.

Materials used:

- Engineering nylons (PA6, PA66) – Mechanical parts

- Acetal (POM) – Gears and precision components

- Glass or carbon-filled grades – Structural strength

- PEEK and PPS – High-temperature applications

Emerging trend: Metal injection molding applications increasingly replace traditional metal fabrication for complex industrial components, offering design freedom impossible with machining.

7. Electrical and Electronic Components

Why injection molding dominates: Electrical components require precise insulation, consistent dimensions, and often integrated features like terminals—perfectly suited for injection molding.

Common components:

- Electrical connectors and terminals

- Switch housings and buttons

- Circuit board supports and spacers

- Electrical boxes and junction housings

- Cable management and routing components

- Appliance control panels

- Light fixtures and sockets

Real-world example: For an electrical connector manufacturer, we developed a two-shot molding process combining rigid nylon for the body with soft TPE for the sealing components. This eliminated assembly steps and improved seal reliability.

Materials used:

- Flame-retardant nylon – Connectors

- PVC injection molding applications – Wire insulation components

- Polycarbonate – Housings requiring transparency

- PBT – Electrical connectors

- Engineering thermoplastics with UL94 ratings

Critical properties: Electrical injection molding applications require materials with specific dielectric properties, flame resistance ratings, and often UL or CSA safety certifications.

8. Aerospace and Defense Components

Why injection molding dominates: Aerospace demands lightweight, high-strength components with exceptional reliability—requirements met through advanced plastic injection molding applications and ceramic injection molding applications.

Common components:

- Interior cabin components

- Ducting and air distribution systems

- Structural brackets and supports

- Control panel housings

- Protective covers and fairings

- Wire harness components

- Sensor housings

Real-world example: We developed PEEK injection-molded brackets for an aircraft interior that replaced aluminum parts. The PEEK components saved 65% weight, cost 40% less, and eliminated corrosion concerns—critical for long aircraft service life.

Materials used:

- PEEK – High-performance structural

- PEI (Ultem) – Heat and flame resistance

- PPSU – Chemical resistance

- Carbon fiber composites – Lightweight strength

- Ceramic injection molding applications – High-temperature sensors

Certification requirements: Aerospace injection molding applications require FAA approval, extensive material testing, and rigorous quality documentation.

9. Furniture and Home Goods

Why injection molding dominates: Furniture components benefit from injection molding’s ability to create aesthetic, ergonomic designs with integrated features at consumer-friendly price points.

Common components:

- Chairs and seating components

- Storage containers and organizers

- Cabinet hardware and brackets

- Decorative elements and trim

- Drawer systems and slides

- Lighting fixtures

- Kitchen utensils and tools

Real-world example: A chair manufacturer we worked with transitioned from thermoformed seat shells to injection-molded designs. The new process added integrated mounting bosses, improved surface finish, and reduced per-unit cost by 45% at their production volume of 200,000 chairs annually.

Materials used:

- Polypropylene – Most common for chairs and storage

- ABS – Durable household items

- Polycarbonate – Transparent components

- TPE – Soft-touch grips and surfaces

Design advantage: Injection molding allows complex ergonomic shapes, integrated features, and textured surfaces that enhance both function and appearance in furniture applications.

10. Agricultural and Garden Equipment

Why injection molding dominates: Agricultural equipment needs UV-resistant, weatherproof components that can withstand harsh outdoor conditions—requirements perfectly matched to engineered plastic injection molding applications.

Common components:

- Irrigation system components

- Sprinkler heads and nozzles

- Tool handles and grips

- Equipment housings and covers

- Seed and fertilizer spreaders

- Planting trays and containers

- Garden hose fittings

Real-world example: For an irrigation manufacturer, we designed glass-filled polypropylene sprinkler bodies that withstood 10+ years of UV exposure, temperature cycling from -20°F to 140°F, and constant water pressure—outperforming previous metal components that corroded.

Materials used:

- UV-stabilized polypropylene – Weather resistance

- Glass-filled nylon – Structural strength

- Acetal – Precision mechanical parts

- Modified PVC injection molding applications – Chemical resistance

Environmental demands: Agricultural applications of injection molding require UV stabilizers, impact modifiers for temperature extremes, and often FDA compliance for food-contact applications.

Emerging Injection Molding Applications

The future of injection molding applications continues expanding into new territories:

Advanced Material Applications

Bioplastics and sustainable materials: Increasing demand for eco-friendly products drives development of injection moldable bioplastics, recycled materials, and biodegradable polymers.

Conductive plastics: Injection molding applications now include EMI shielding, static-dissipative components, and even electrically conductive structural parts.

Nano-enhanced materials: Adding nanoparticles creates injection-molded parts with enhanced strength, thermal conductivity, or barrier properties previously impossible.

Process Innovations

3D-printed molds for rapid prototyping: Short-run reaction injection molding applications using additive manufacturing tooling enable faster product development.

In-mold assembly and electronics: Integrating electronics, sensors, and multiple materials during the molding process creates smart, connected products.

Micro-injection molding: Medical and electronics applications increasingly require microscopic precision parts under 1 gram.

Selecting the Right Process for Your Application

When evaluating injection molding applications for your product, consider:

Production volume requirements:

- Under 1,000 parts: Consider alternatives like 3D printing or machining

- 1,000-10,000 parts: Low-volume tooling may be viable

- 10,000-100,000 parts: Standard production tooling justified

- Over 100,000 parts: High-cavity molds optimize cost

Material requirements:

- Commodity plastics: Standard plastic injection molding applications

- High-performance: Engineering grades or metal injection molding applications

- Biocompatibility: Medical-grade materials with certifications

- Specialized properties: Ceramic injection molding applications or reaction injection molding applications

Geometric complexity:

- Simple shapes: Many manufacturing options available

- Complex geometries: Injection molding often only viable option

- Integrated features: Molding excels at snap fits, threads, bosses

- Large parts with thick sections: Consider reaction injection molding applications

Economic analysis:

- Calculate tooling amortization over production volume

- Compare per-part cost across manufacturing methods

- Factor in assembly elimination through integrated design

- Consider total cost including secondary operations

Conclusion

Injection molding applications have transformed manufacturing across virtually every industry. From the 5 trillion packaging components produced annually to sophisticated metal injection molding applications in medical implants, injection molding’s versatility and efficiency continue driving innovation.

After 14 years working across diverse injection molding applications, I’ve learned that success requires matching process capabilities to application requirements. Plastic injection molding applications dominate consumer products and packaging. Metal injection molding applications excel for complex precision components. Ceramic injection molding applications solve high-temperature and wear challenges. PVC injection molding applications provide chemical resistance and durability.

The key is understanding your specific needs—production volume, material properties, geometric complexity, and cost targets—then working with experienced manufacturers to select the optimal approach.

As materials science advances and process technologies improve, new applications of injection molding emerge constantly. What seemed impossible five years ago—molding ceramics with complex geometries, integrating electronics during molding, or achieving true sustainability with bio-based materials—is now reality in production applications.

Whether you’re developing consumer products, medical devices, automotive components, or industrial equipment, injection molding likely offers solutions that deliver the quality, efficiency, and economics your project demands. The applications covered here represent just a fraction of injection molding’s current capabilities, with new possibilities emerging as technology advances.

FAQs

Which industries see the fastest payback from injection molding?

Automotive trims, healthcare disposables, smart‑home enclosures, and caps and closures typically reach ROI quickly thanks to predictable volume and tooling amortization.

How can I minimize cosmetic issues on visible housings?

Balance gates, place knit lines away from sight areas, match steel texture to the final finish, and approve color on production‑intent tools before locking specifications.

When is overmolding the right choice?

Choose it for integral seals, soft‑touch grips, or color accents without secondary assembly. Validate material compatibility and bond‑line cleanliness early in trials.