If you’ve ever struggled with strange clogs or messy extrusions in your 3D printing, you might be facing heat creep 3d printing issues. It’s frustrating when you set up a big print only to discover halfway through that the filament is jamming or the layers look inconsistent. The cause often lies in a small but critical section of your hot-end assembly.

You might be asking: “What exactly is heat Creep 3D Printing?” and “How do I spot it before it ruins my prints?” Essentially, heat creep occurs when excess heat travels upward from the hot nozzle into areas of the filament path that are supposed to stay cool. This can soften the filament prematurely, leading to blockages, poor extrusions, and other head-scratching print defects.

In this article, we’ll delve into common signs of heat creep, explore the factors contributing to it, and offer practical advice on spotting and preventing these issues. Whether you’re a casual hobbyist or an avid printer, understanding heat creep can help you maintain smoother, more reliable prints.

Heat Creep 3D Printing: Symptoms

When dealing with heat creep 3d printing, keep an eye out for clogs, uneven extrusion, and odd filament appearances. These symptoms often hint that excess heat is traveling up the hotend. By identifying the cause—like poor cooling or excessive nozzle temperatures—you’ll avoid jams and get back to flawless prints.

Clogs in the Heat Break

A major sign is a filament that can’t push through the nozzle. This might happen when softened plastic blocks the narrow heat break channel. If you’re fighting frequent jams, your issue likely stems from heat creeping upward, melting filament where it shouldn’t.

Inconsistent Extrusion Patterns

Inconsistent flow leaves gaps or spongy layers in your model. You might see sudden stops in extrusion followed by spurts of plastic. These waves of material output can often be traced back to heat creep. Fixing it restores steady, uniform lines.

Material Leaks and Ooze

The prematurely melted filament may seep from the nozzle whenever the printer pauses. This can leave tiny blobs, create stringing between travel moves, or lead to sticky lumps on surfaces. Properly controlling the heat zone in the hotend keeps your material in check.

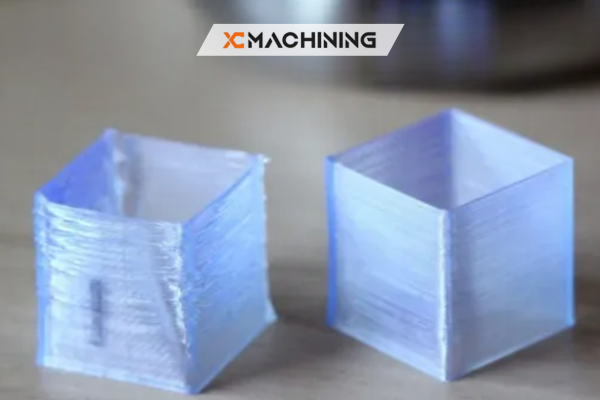

Closer Look at Clogging

Clogging is one of the most common signs of heat creep 3D printing, and it’s also the most aggravating. You start a print with high hopes, only to see your nozzle jam a few minutes or hours in. Clearing the obstruction can be tedious, often involving a cold pull or partial hotend disassembly.

Why does this happen? The typical culprit is the filament that’s softened too high in the hotend, forming a plug. The extruder motor can’t push filament past this semi-melted lump, leading to a jam. As soon as that jam occurs, you’ll notice the printer extruding little to no Multi-material 3D Printing, and you may hear the extruder motor clicking or skipping.

Info: Sometimes, you can push the clog through by raising the nozzle temperature. But this only masks the root cause if heat creep is to blame. A permanent fix involves improving cooling and ensuring the hot zone stays in the right place.

Inconsistent Extrusion and Missing Layers

Heat creep doesn’t always completely clog your nozzle. Sometimes, it just teases you with sudden stops and starts in the flow. This leads to inconsistent extrusion, which can be spotted in your print layers. Instead of neat, continuous lines of filament, you see random gaps, especially in walls or infill patterns.

When heat creep 3d printing issues cause inconsistent flow, the print may still finish, but it’ll look rough. The outer walls could have visible bumps or holes. Overhangs might droop. Internal structures can become weak, leading to a fragile final 3D printer parts. If you suspect extruder problems, always consider heat creep alongside other factors like tension or retraction settings.

Reasons for Uneven Layers

- Semi-Melted Filament Build-up: Filament gets softer than intended before the nozzle, restricting flow.

- Cooling Fluctuations: If your cooling fan falters, the hot end can overheat quickly.

- Over-Retraction: Pulling warm filament into cooler zones.

- High Ambient Temperature: The printer environment might be too hot for proper heat dissipation.

Quick Tip: Before you fiddle with your slicer settings, do a quick hardware check. Ensure your hot end fan works properly and the heat sink is free of dust or obstructions.

Material Oozing and Warping

Sometimes, heat creep 3D printing troubles are present more subtly. You might notice your filament drooling from the nozzle during idle time. Or the spool globs up on the print bed, even when the printer is waiting between extrusions. This phenomenon indicates that the filament is softening prematurely in the hot end.

Oozing and Stringing

Oozing can also cause stringing, those thin hair-like strands between separate parts of your model. While stringing is often linked to retraction settings, heat creep can also amplify the problem. If your filament remains soft and runny in the hotend’s upper region, you’ll see more dripping each time the print head moves.

Warping and Poor Bed Adhesion

A less obvious symptom of heat creep 3D printing might be warping. When filament flow is inconsistent, the extruded material can cool unevenly or not bond properly to previous layers. That imbalance can lead to edges lifting off the bed or corners curling. If you’re battling random warping that your typical bed adhesion methods don’t solve, consider checking your hotend’s heat management.

Warnings: Warping can also result from other factors like bed temperature or drafty enclosures. Evaluate all variables before blaming heat creep exclusively.

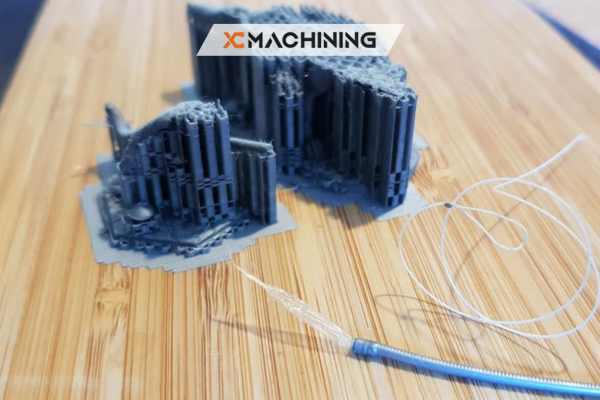

“Air Bubbles” on the Filament

One of the more surprising symptoms is seeing small deformities or bubble-like marks on the filament when you pull it out of the hot end. Typically, the filament leaving the nozzle should be a smooth strand. But if you notice lumps, air pockets, or tiny craters, that’s a strong hint of heat creep 3d printing.

Why do bubbles form? If the filament melts in the wrong place, pockets of air or moisture can get trapped. That trapped air expands or evaporates, creating little bubble patterns. This is particularly common with filaments stored in humid conditions. Combined with improper heat control, the result is a bubbled, irregular surface.

Factors to Watch

- Filament Quality: Cheap or moist filaments can encourage bubble formation.

- Excessive Temperatures: Running your hotend too hot breaks down the plastic, producing gases.

- Inconsistent Feed Rate: Jerky feeding or retractions pulling partially molten filament into cooler areas.

If you spot these bubbles, you’ll likely experience clogs or messy prints soon after. Identifying them early can prevent further nightmares.

Suggestion: If you suspect moisture, dry your filament in a dedicated filament dryer or a low-temperature oven before use. Reducing moisture helps combat bubble issues.

Factors That Contribute to Heat Creep 3D Printing

Knowing the symptoms is great, but you’ll also want to understand why heat creep 3d printing happens. A variety of conditions can trigger it, and sometimes it’s more than one cause combined.

Inadequate Cooling

A reliable cooling fan for the hotend’s heat sink is essential. If the fan is undersized or broken, heat from the nozzle travels upward. Dust, debris, or poorly placed wires blocking airflow can similarly reduce cooling power.

| Cooling Issue | Impact on Hotend | Possible Fixes |

|---|---|---|

| Fan Failure | No airflow, major creep | Replace the fan or check the wiring |

| Blocked Heat Sink | Heat builds up quickly | Clean vents, remove dust |

| Wrong Fan Placement | Partial air coverage | Reposition or upgrade the cooling fan |

Info: Ensure you’re using the correct fan for your hotend model. Some printers rely on a dedicated part-cooling fan plus a separate hotend fan. Don’t mix them up.

Excessive Hot End Temperature

Running your nozzle far above the recommended range for your filament can drive too much heat up the assembly. While it’s tempting to crank up temperatures to speed printing, it can backfire. Lowering the temperature or using a nozzle appropriate for high temps can help.

High Ambient Temperatures

Printing in a warm environment—like a heated enclosure or a hot garage—hampers heat dissipation. This intensifies heat creep 3d printing issues, so you need to keep your printer ventilated or tune your cooling strategies accordingly.

Excessive Retraction

Pulling the filament backward too often or too far can drag softened plastic into the cooler zones of the heat break. Over time, it sticks, forming partial blockages. Reducing retraction distance or frequency could ease your heat creep woes.

Poor Thermal Design

Some hotend styles are more prone to heat creep than others. If you have a budget or older 3D printer, the heat break design might not effectively isolate the hot zone from the cold zone.

Filament Quality

Don’t overlook the role of subpar filament in heat creep 3d printing. Cheap or older filaments might melt at lower temperatures, degrade faster, or contain impurities. These traits make them more likely to clog in borderline temperature conditions.

Danger: If your hotend or extruder design is faulty, no fan or temperature tweak may fix heat creep permanently. In extreme cases, consider upgrading to a well-reviewed hotend with a proven track record of minimal heat creep.

Conclusion

So, what are the signs of heat creep 3D printing? Look for clogs, inconsistent extrusion, oozing, random warping, and bubble-like deformations on your filament. These red flags suggest heat is creeping higher than it should, softening your plastic before it reaches the nozzle tip. By checking for insufficient cooling, reducing overly high temperatures, and fine-tuning retractions, you can mitigate or eliminate heat creep from your 3D printing routine.

Ultimately, a cool and properly managed hotend ensures smoother filament flow, better layer consistency, and fewer headaches overall. Staying aware of the symptoms and addressing them quickly keeps your printer humming so you can keep those 3D creations coming.

FAQs

- Does heat creep only affect certain types of filament?

No. While some filaments like PLA may be more prone due to lower melting points, heat creep 3d printing can happen with almost any thermoplastic if the hotend setup is inadequate.

- Can I solve heat creep by simply lowering my print temperature?

Often, yes. Reducing temperature helps slow heat conduction upward. But you may also need to enhance cooling or adjust retraction to see real improvements.

- Will adding a different nozzle size fix heat creep 3d printing?

Not directly. A larger nozzle may reduce back pressure, but if your cooling is poor, heat will still travel up. Aim for a more holistic approach.