Have you ever heard someone rave about “printing” a phone case or a miniature car engine at home and wondered, “Wait, what is 3D printing, and why is everyone so excited?” You’re not alone. Many people find this technology fascinating but aren’t quite sure how it works or what it can really do for them. Some worry it’s too complex or too expensive, while others think it might be only for large factories.

In this blog, we’ll uncover exactly what is 3D printing about and explore its wide-ranging applications. By the end, you’ll understand the surprising ways 3D printing shapes our world—and maybe you’ll even want to try it for yourself.

What Is 3D Printing: The Basics?

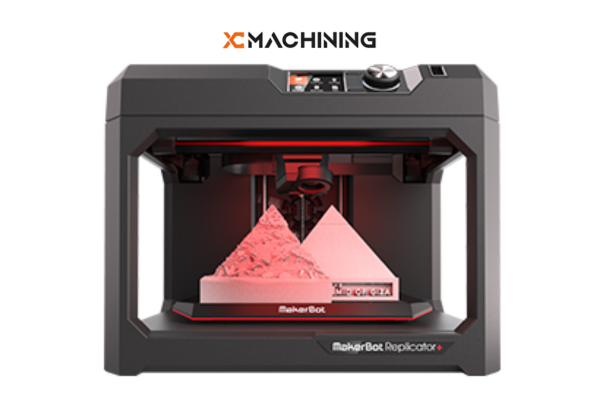

First, we need to know what is 3D printing. We’ll look at a few foundational aspects so you know exactly what’s happening when that printer hums to life. 3D printing is a process where a machine follows digital instructions to “draw” or “build” an object layer by layer. Instead of cutting away material like traditional manufacturing, it adds material exactly where it’s needed. Different printers use different materials—plastics, metals, ceramics, or even food-based substances.

How Layers Are Created

Printers interpret computer files called 3D models. These files are sliced into thin layers, each representing a single cross-section of the final object. The printer deposits or solidifies material layer by layer until the entire piece is formed. If you’re still asking yourself, what Is 3D printing? in practical terms, it’s basically a method of stacking these layers in a precise way to form complex shapes.

Material Options

Plastics like PLA or ABS are common for beginners, while industrial machines use metals, high-performance plastics, or even carbon fiber. The type of material often depends on the end use—lightweight prototypes, durable machine parts, or medical implants with special properties.

Types Of 3D Printers

Different printing technologies exist, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each comes with unique advantages. FDM is popular for hobbyists, SLA offers smoother surfaces, and SLS handles advanced materials for high-end industrial applications. Exploring these helps answer what Is 3D printing? in terms of technology choices.

Early Prototyping And Rapid Iteration

Before diving into specific industries, let’s talk about prototyping. For decades, creating prototypes meant weeks of machining or molding. 3D printing changed that dramatically, letting companies and individuals whip up a sample part in hours. If it’s not quite right, they adjust the design and print again. This rapid-fire approach saves both time and money.

- Lower Costs: You only use as much material as the part requires, reducing waste.

- Speed: Days turn into hours.

- Design Freedom: Complex geometries aren’t as big of a headache as they are with traditional methods.

Fact: According to a study by Deloitte, rapid prototyping can shorten product development cycles by up to 50%, leading to quicker market launches.

Automotive Industry Innovations

Car manufacturers were among the first to embrace what Is 3D printing. They found it perfect for custom parts, prototypes, and even final components. Engineers can test various designs swiftly without the lead time of traditional tooling. Entire concept cars sometimes feature multiple 3D-printed parts, from intricate dashboards to custom engine components.

3D printing in the automotive world also extends to replacement parts. Need a rare piece for your classic car? Sometimes, it’s easier to 3D print a replica than to search junkyards or pay a fortune for a custom machinist.

Suggestion: If you’re into cars, consider a small 3D printer to create custom badges or interior accents. It’s a fun way to personalize your vehicle without breaking the bank.

Aerospace And 3D Printing

3D printing helps reduce weight in aircraft, which is critical for fuel efficiency. Companies like Boeing and Airbus use this technology to produce lightweight, complex structures that would be nearly impossible or extremely costly to manufacture otherwise. These parts can be anything from brackets to entire interior components.

Astronauts at the International Space Station even have a 3D printing in prototyping on board. Instead of waiting months for specific tools, they can print them as needed. This on-demand manufacturing approach saves space, money, and time—key concerns when you’re orbiting Earth.

Danger: Aerospace applications demand high material quality and precise manufacturing settings. A slight flaw in the structure can have massive safety implications. Strict quality control is essential.

Healthcare: Prosthetics And Beyond

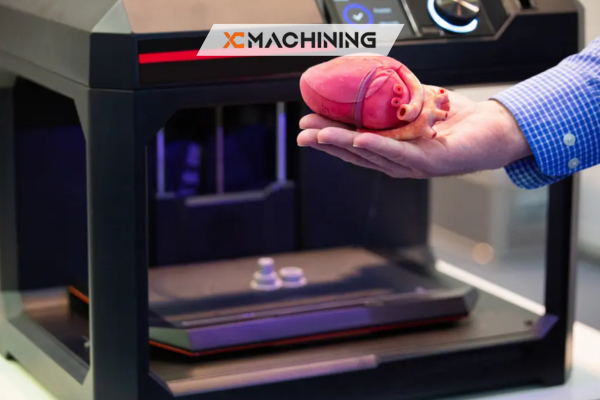

Healthcare might be one of the most heartwarming applications of what Is 3D printing. Imagine having a prosthetic limb tailored perfectly to your unique measurements and needs. That’s now possible, and often at a fraction of the cost of traditional prosthetics. Hospitals also print surgical models so doctors can plan complicated procedures more accurately.

Dentistry is another field benefiting from what Is 3D printing. Custom aligners and dental implants can be produced swiftly, ensuring a better fit for patients. The next frontier? Bioprinting human tissues and organs. While still in development, scientists are working toward printing functional body parts, such as heart valves or cartilage.

Quick Tip: Some charities use low-cost 3D printers to produce prosthetic hands for children in developing countries. This approach can transform lives and communities.

Consumer Goods And Personalized Items

When people ask, “What is 3D printing used for in everyday life?” the consumer goods sector is a great answer. Companies can now offer personalized products at scale, from custom phone cases to tailored footwear. If you can dream it up, you can probably 3D printing metal it.

Fashion designers have also jumped on board. 3D-printed dresses, jewelry, and accessories are appearing on runways, showcasing complex patterns that would be impossible to create by hand. While these items might be niche or high-end right now, the technology is steadily trickling down to more mainstream markets.

Info: Some sneaker brands use 3D printing for midsoles, offering improved cushioning and design flexibility compared to traditional foam molds.

Architecture And Construction

The construction industry is eyeing 3D printing to build houses and offices faster and cheaper. Specialized giant printers layer concrete or other building materials to form walls. This can cut labor costs dramatically and speed up construction in regions needing rapid housing solutions.

Architects also use tabletop what is 3D Printing to create scale models of their designs. This allows clients to hold a miniature building in their hands and understand the layout more intuitively than they would from 2D blueprints. It’s a game-changer for design validation and client presentations.

Warnings: Large-scale 3D printing of homes is still experimental in many places, so safety regulations and building codes can vary. Always consult local laws before attempting to build a 3D-printed structure.

Education And STEM Learning

Schools and universities love 3D printing because it brings theories to life. Students can design their own parts in CAD software and then watch them materialize. It’s a fantastic way to teach engineering, design thinking, and problem-solving skills. Plus, let’s face it—students find it really fun to see their creations pop out of a machine.

Many libraries and community centers also host “maker spaces” with shared 3D printers. These spaces encourage people of all ages to learn about digital fabrication. Whether it’s a robotics club printing specialized brackets or an art student experimenting with sculpture, the possibilities are endless.

Suggestion: If you have kids interested in engineering, check if your local library or school has a 3D printer. It’s a hands-on way to spark creativity and curiosity.

Food 3D Printing

Yes, you read that right—you can 3D print food. Some high-end restaurants use edible “ink” like chocolate, dough, or pureed ingredients to create shapes that would be nearly impossible by hand. Imagine a dessert shaped like a delicate lattice or a perfectly symmetrical garnish.

While still somewhat novelty-driven, food 3D printing can reduce waste by carefully controlling portions. It also allows for creative plating and custom diets. People with specific dietary restrictions could get meals designed for their exact nutritional needs. It’s a niche field for now, but it’s growing.

Fact: The first 3D-printed burger (made from lab-grown meat) was introduced a few years ago, showing that food manufacturing might significantly shift in the coming decades.

Art, Jewelry, And Cultural Preservation

Artists and jewelers have embraced what Is 3D printing for its ability to create intricate, one-of-a-kind pieces. A sculptor can experiment with forms that would be nearly impossible to carve by hand. A jeweller can print a wax mold for a ring and then cast it in metal for a flawless finish.

Museums and cultural institutions also use 3D printing for preservation and education. Ancient artifacts can be scanned and replicated, letting people handle realistic models without risking damage to the originals. This approach opens new doors for interactive exhibits and global sharing of cultural treasures.

Quick Tip: If you’re a beginner with an artistic streak, start by printing small, simple sculptures. Experiment with different filament colors and finishes to see what inspires you.

Sustainability And Reduced Waste

If you’re wondering, what is 3D printing? in terms of sustainability, it refers to an additive process that places material only where needed. Traditional manufacturing often involves cutting away material from a larger block, which generates waste. 3D printing is additive, meaning it only uses what’s necessary. This reduces leftover materials, which is good news for the environment and your wallet.

Additionally, some 3D printer cost can use recycled plastics. This approach takes waste like plastic bottles and transforms them into printable filament. Although not yet widespread, it hints at a more sustainable future where manufacturing and recycling go hand in hand.

Sustainability Highlights

- Reduced scrap due to additive process.

- Potential to reuse plastics from packaging or bottles.

- On-demand manufacturing reduces excess inventory.

- Less energy consumption in some workflows.

- Custom, eco-friendly designs for greener products.

Military And Defense Applications

3D printing has also made its mark in the military sector. Portable what Is 3D printing can be taken to remote locations to create spare parts on the spot. Imagine a broken vehicle or drone part—rather than wait weeks for shipment, troops can print what they need.

The defence industry also invests heavily in research for advanced materials and printing techniques. These might include heat-resistant alloys or lightweight composites, aiming to make military equipment more efficient and reliable.

Danger: While 3D printing can aid defence, it can also raise concerns about the potential for creating untraceable weapon components. Regulations often lag behind technological advances, so this remains a complex issue.

Fun DIY Projects And Hobbies

Many 3D printing enthusiasts share their works-in-progress online. Wondering what Is 3D printing? from a hobbyist standpoint? It’s essentially the ultimate sandbox for creativity. Hobbyists use it to print cosplay accessories, board game components, custom phone stands, or even fix random household items. The sense of accomplishment is huge when you snap a broken plastic piece from your vacuum, measure it, model it in 3D, and print a perfect replacement.

Community: One of the best parts of the hobby is the online community. Sites like Thing verse offer countless free designs you can download and print right away. This collaborative spirit accelerates innovation and ensures there’s always something new to try.

Info Box: Many 3D printing enthusiasts share their works-in-progress on social media. It’s a great way to learn tips and tricks, plus get feedback on your designs.

Real-World Examples Table

Below is a numeric-based table showcasing various industries and specific 3D-printed applications. This quick snapshot helps you see how broad the scope really is.

| No. | Industry | Application | Notable Example |

|---|---|---|---|

| 1 | Automotive | Custom car parts | Ford using 3D-printed prototypes |

| 2 | Aerospace | Lightweight aircraft components | Boeing printing titanium parts |

| 3 | Healthcare | Prosthetics and implants | Custom-fitted implants for patients |

| 4 | Consumer Goods | Personalized products | Custom phone cases, footwear |

| 5 | Construction | House building and scale models | 3D-printed homes in China |

| 6 | Food | Complex edible designs | 3D-printed chocolate garnishes |

| 7 | Art/Jewelry | Intricate sculptures and molds | Precious metal casting via wax printing |

| 8 | Education | Classroom projects, prototypes | STEM programs using FDM printers |

| 9 | Military | On-demand spare parts | Field-deployed portable printers |

Conclusion

By now, you can see that what is 3D printing doesn’t just refer to a fancy hobby or a gimmick. It’s a powerful technology that transforms entire industries—from healthcare to construction, from art to aerospace. Through layering materials precisely where needed, 3D printing speeds up prototyping, reduces waste, and makes personalization easier than ever.

In short, What Is 3D Printing and offers the freedom to design without many of the constraints of traditional manufacturing. Whether you’re building a custom phone case at home or a spacecraft bracket in an aerospace facility, the process remains remarkably similar. That’s the true beauty of 3D printing—it unlocks creativity at both large and small scales.

FAQs

Q: Can I 3D print with metal at home?

Home metal printing is still rare because metal 3D printers are expensive and often require special conditions. However, some desktop machines can handle metal-infused filaments, which contain a blend of plastic and metal powder.

Q: Is 3D printing expensive to start with?

Entry-level machines can be found for a few hundred dollars. The cost mostly depends on your desired print quality and material variety. Filament prices are reasonable, but specialized materials cost more.

Q: Do I need design skills to start 3D printing?

Not necessarily. Many free, ready-to-print models exist online. However, learning basic 3D modelling can help you create custom items. Tools like Tinkercad and Fusion 360 are popular for beginners.