Have you ever found it difficult to remove intricate supports from 3D-printed pieces without destroying them? If so, you may have questioned, “What Is PVA Filament” and how it might aid in generating more even outcomes. PVA, or Polyvinyl Alcohol, is a water-soluble substance that melts in dampness. In dual-extrusion 3D printing, you can create complex forms or overhangs with fewer cleanup hassles, which makes it very helpful as a supporting structure.

Simplistically, then, what is PVA filament? Derived from vinyl polymer, this biodegradable plastic is made of standard building materials like PLA or ABS. PVA supports can easily be removed by soaking the print in water. This dissolvable property simplifies post-processing. If you want crisp edges and minimal sanding on complicated prints, PVA could be the best support choice around. In this blog, we’ll delve deeper into the properties of PVA, how it’s applied in 3D printing, and tips for successful usage.

What Is PVA Filament? Understanding The Composition Of PVA

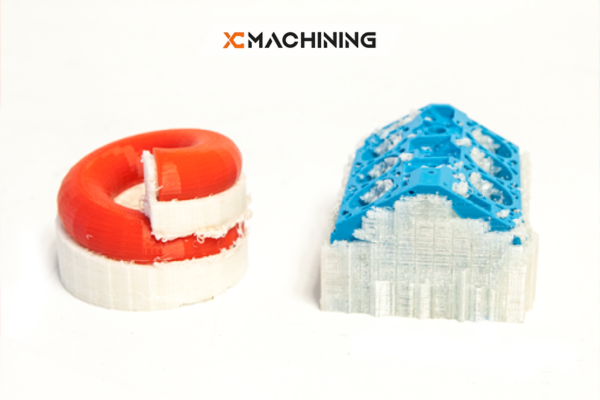

What is PVA filament? It’s a water-soluble plastic commonly used as a support material in dual-extrusion 3D printing. PVA helps form stable scaffolding for complex designs, then dissolves in water, leaving a clean final piece. With proper storage, it produces minimal residue and easy overhang solutions.

Dissolvable Supports

PVA dissolves completely in water, eliminating manual clipping of support structures. This feature reduces part damage and keeps surfaces smooth. Designers rely on PVA to create internal channels or hidden details that would be impossible with conventional breakaway supports.

Dual Extrusion Friendly

Many 3D printers now include dual extruders. One extruder prints the main part, while the other lays down PVA for support. This combination streamlines complex prints, allowing greater design freedom without the hassle of physically removing delicate support pieces.

Sensitivity To Moisture

Because it absorbs moisture easily, PVA must be stored in airtight containers. Even slight humidity can cause the filament to swell or jam in the nozzle. If you spot bubbles or stringiness, your filament likely picked up extra moisture along the way.

Ideal Printing Conditions

It’s not enough to ask what is PVA filament without also learning about the optimal environment for using it. Temperature control, bed adhesion, and extrusion settings are crucial. Typically, PVA prints well in the 180°C to 220°C range, though exact temps vary by brand.

A heated bed around 50°C to 60°C often helps keep PVA layers stable. However, if you’re combining PVA with other materials (like PLA, which might need a bed temperature of around 60°C), find a compromise that suits both. Adequate calibration is key, or you risk excessive oozing from the PVA nozzle.

Because of PVA’s solubility, controlling moisture during the print is paramount. If your spool has absorbed water, you might see steam or sizzling noises from the extruder. Drying the filament in a specialized filament dryer or an oven at a low temperature can restore its performance.

Dual-Extrusion Setup

One major advantage of PVA is its synergy with dual-extruder 3D printers. The second extruder handles the PVA spool, placing supports only where needed. Meanwhile, the first extruder lays down your main build multi-material 3D printing (like PLA, PETG, or nylon).

This approach is game-changing for complex prints. Instead of designing intricate breakaway supports or worrying about bridging in tight areas, you can let the PVA handle it. Then, once the print finishes, a simple soak dissolves the what is PVA filament away, revealing crisp overhangs.

Setting up a dual-extrusion job might involve special slicer settings. Often, the software merges two separate STL files or uses a single file with distinct meshes. Ensure your slicer aligns each extruder’s prime settings so that the PVA transitions smoothly when the nozzle changes from one material to the next.

Applications In Complex Design

What is PVA filament good for if not pushing the boundaries of 3D design? When you’re printing a part with intricate channels or cavities inside, standard supports might be impossible to remove. PVA supports, however, simply dissolve away from every internal area.

Think of biomedical models featuring interior cavities that mimic organ structures. Or functional prototypes requiring internal fluid pathways. With what is PVA filament, you print those channels in place, soak the part later, and let water do the rest. It’s an elegant solution that’s changed how engineers approach design-for-manufacturing.

Even small consumer pieces with tricky overhang geometry can benefit. A figurine with delicate wings or a vase with branching patterns becomes more feasible with water-soluble supports. The final result often has fewer surface marks and less risk of breakage during support removal.

Solubility And Dissolving PVA

After printing, the big question arises: how do you remove PVA without damaging the main model? The answer is a simple water bath. Once submerged, the PVA typically starts dissolving within minutes, though thicker layers may take hours.

Using warm water can speed the process, but avoid water that’s too hot, as it might warp your primary filament if it’s sensitive (like PLA). Gently stirring the water helps freshwater reach all 3D printer parts of the support. Alternatively, partial mechanical removal might hasten dissolution if you carefully peel away large lumps first.

For multi-day dissolves, consider changing the water periodically. This keeps the solution from becoming oversaturated with what is PVA filament remnants and helps maintain the dissolution rate. You can also use ultrasonic cleaners for especially complex prints, but always confirm your main material can handle such treatment.

Info: If you notice a slimy residue on your model after soaking, rinse it further or let it sit under running water to remove any final PVA traces.

Storing PVA Filament Properly

People often ask, “What is PVA filament doing in my spool after months of storage, and why is it so brittle?” That brittleness or poor printing performance often stems from moisture absorption. PVA is hygroscopic, meaning it loves to soak up ambient humidity.

Keep your spool sealed in an airtight bag with desiccant packs. If you live in a humid climate, an active filament dryer or sealed container is a must. Periodically check the dryness of the desiccant, replacing it if it becomes saturated.

In general, treat PVA with more caution than PLA or ABS. If you notice the spool feels damp or see tiny bubbles while extruding, dry it in a filament dryer at around 40–50°C for a few hours. This practice can revive your spool’s print quality significantly.

Combining PVA With Other Filaments

Because PVA is typically used as a support, it rarely stands alone for entire prints. Instead, it pairs with common build filaments like PLA, ABS, or PETG. The rule of thumb is to ensure both materials have somewhat compatible print temperatures and bed adhesion profiles.

For instance, PLA prints around 200°C, which is also comfortable for PVA, which melts around 190–220°C. Combining ABS (which needs about 230°C) can get trickier, but some advanced PVA blends can handle moderate spikes in temperature. If your main filament prints above 240°C, though, standard PVA might degrade, forcing you to look for specialized support filaments.

This synergy is also about bed adhesion. If your main filament needs a 60°C bed, but your PVA spool suggests 45°C maximum, find a middle ground or print with minimal bed heat if possible. Testing each brand’s recommended temperature range helps you fine-tune the best compromise.

Printing With PVA For Artistic Creations

What is PVA filament bringing to the artistic realm? Think of intricate sculptures or decorative models with zero unsightly support marks. Artists can harness water-soluble scaffolding to create illusions of floating elements or hidden negative space.

For example, a complex cityscape model might feature dozens of small windows and spires. Using normal supports could cause messy scars or near-impossible removal. With PVA, those spires remain perfectly intact once the supports dissolve.

Some 3D artists also embed PVA in creative ways, using partial dissolution to produce textures. By controlling how long the piece soaks, they can create swirling patterns or partial holes. Although this technique is experimental, it highlights PVA’s potential beyond mere utility.

Quick Comparison Of PVA Vs. HIPS (Another Support Filament)

Below is a snapshot comparing PVA to HIPS, another support option that dissolves in limonene:

| Aspect | PVA Support | HIPS Support |

|---|---|---|

| Solvent | Water | Limonene solution |

| Print Temp Range | 190–220°C (typical) | ~230°C or higher |

| Ease Of Removal | Very easy in water, no strong odor | Limonene can be smelly and may leave residue |

| Material Pairing | Commonly with PLA, some PETG variants | Often used with ABS or higher-temp materials |

| Storage Need | Desiccant, low humidity | Less moisture-prone but still recommended dry |

Both filaments have unique perks. PVA stands out for water-based removal, while HIPS pairs nicely with ABS. Choose the solution that fits your main filament’s temperature and your personal tolerance for chemicals.

Conclusion

In 3D printing, what is PVA filament used and why? Popular construction filaments like PLA fit this water-soluble support material really nicely. PVA can be combined with dual extrusion to create extremely finely detailed items with little post-processing work. For delicate structures, interior channels, and complicated overhangs, the water-dissolvable quality changes everything.

In essence, the 3D printing toolbox consists mostly of what is PVA filament. Yes, it requires some additional understanding and cautious preservation; the benefits are well worth it. You get cleaner prints, fewer structural scars, and more design freedom. Whether you’re prototyping advanced engineering parts or crafting intricate art pieces, PVA supports can transform your printing approach. By understanding temperature ranges, dryness requirements, and the right partner filament, you’ll unlock the full potential of water-soluble supports.

FAQs

- How fast does PVA dissolve in water?

It depends on thickness and water temperature. Thinner supports might dissolve in 15–30 minutes, while thicker chunks can take hours. Warm water speeds things up.

- Can I use tap water to dissolve PVA, or should it be distilled?

Tap water generally works fine. Distilled water might accelerate or even out the process, but it’s not mandatory.

- Is PVA filament safe to handle?

Yes, but keep it dry. It’s non-toxic, though ingesting it isn’t recommended. Wear gloves when handling partially dissolved material, as it can get sticky and messy.