Vacuum casting is a blend of both preciseness and craftsmanship, which transforms a single master model into as many perfect replicas as it can handle with meticulousness, expediency and an exceptional surface finish.

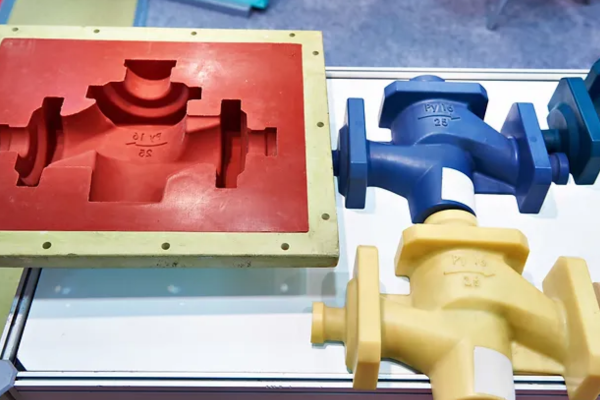

Master Model Development

A high quality master model is produced typically by CNC machining or 3D printing and the first step is to start with this master. It is used as a model in order to have all the minute details that will be replicated in the final sections.

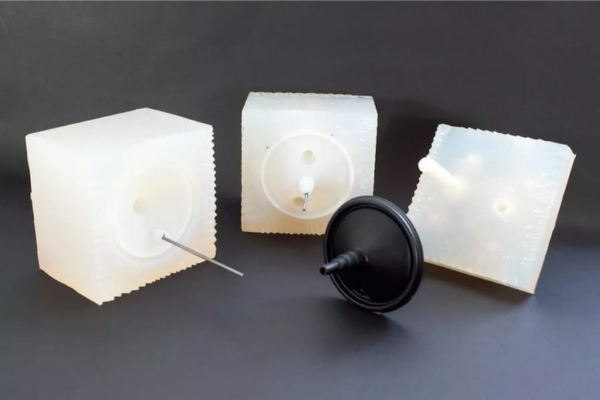

Silicone Mold Making

The master model is cast in a casting frame and an ample amount of liquid silicon rubber is added around the model. After the silicone is cured, it is slit open to create a mold that will give a hole with an anatomy that perfectly fits that of the master model.

Mold Preparation

Reconstruction of the silicone mold halves is done, and then inserted into a vacuum chamber. This is to eliminate any air entrapment so that the resin would fill in every detail with no bubbles and voids.

Vacuum Resin Pouring

It is poured into the mold when mixed with a polyurethane resin and is under vacuum conditions. The Vacuum facilitates consistency in the spread of the resin with sharp edges and fine textures perfectly captured.

Resin Pouring Under Vacuum

The loaded mold is put into an oven where it is heated uncontrollably at a normal range of 2 to 4 hours. It also enables the resin to be hardened and develop desired strength and durableness.

Demolding

The silicone mold is opened slowly after it has been cured in order to retrieve the finished part. The molds are capable of approximately 15-25 parts before it will lose its accuracy.

Finishing

This component is mechanically cleaned and then cut, as necessary, and any required decorative effects to surfaces, thus ready to be put into functional service, or be exhibited.

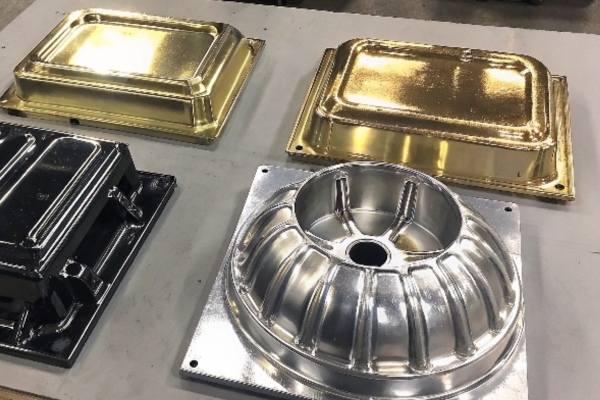

What Are The Challenges in Vacuum Casting?

On short runs, vacuum casting is able to produce parts with injection-mold quality but depending on the effect of elements such as mold wear and resin character, cost, accuracy, and the production time are vulnerable.

Limited Mold Lifespan

Vacuum casting Silicone molds typically have a limited life, making 1525 parts at most, until they lose accuracy. The wear of the mold surface has a long-term drawback on the level of detail and the quality of surface finish. This renders it most suitable for small-run production.

Material Limitations

Polyurethane resins are most frequently deployed in vacuum casting, and are able to recreate the look and feel of typical plastics. Nevertheless, they are unable to emulate the mechanical behaviors of the high-performance engineering materials, such as PEEK or fiber-reinforced polymers, which restrict their applicability to high-stress practices.

Shrinkage and Dimensional Variations

Polyurethane resins contract during curing by about 0.2 0.5 percent. Failure to consider this may lead to the production of metal parts that are marginally undersized or out of specification, where they have to be corrected in the master design.

Detail Degradation Over Time

Silicone molds are reused and therefore, fine textures, and sharp edges wear down. This information loss operates on the practical accuracy of parts, as well as their aesthetic quality, particularly where a design depends upon complex patterning.

Time Constraints for Complex Designs

Complex components would need extra mold impressions, vacuum series or finishing procedure. Such additional operations may increase lead times, especially in the case of complex shapes, or in complex assembled parts.