Selective Laser Sintering (SLS) is a powerful 3D printing technology that uses a laser to sinter powdered material into solid parts. Unlike traditional 3D printing methods that deposit material layer by layer, SLS selectively fuses fine particles of material, such as plastic or metal powders, to create complex and durable parts. This process is ideal for producing high-performance components, particularly for industries requiring strong, functional parts with intricate geometries.

Our advanced SLS technology enables us to create precise, high-quality parts with remarkable strength, making it an excellent choice for rapid prototyping, small production runs, and custom manufacturing solutions.

How Selective Laser Sintering (SLS) Works?

The SLS process involves the use of a laser to fuse powdered material layer by layer, creating a solid part from a 3D digital model. Here’s a detailed overview of how SLS works:

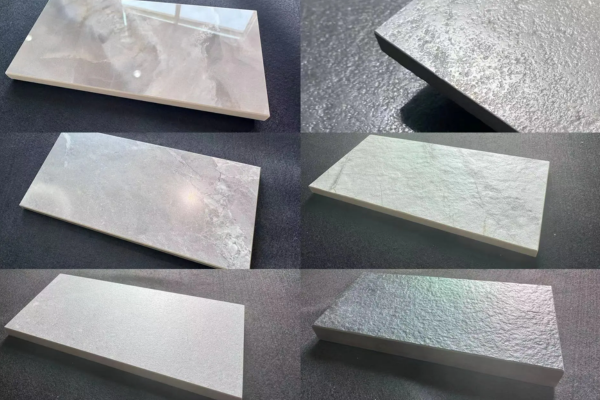

- Material Selection: The process begins by selecting a suitable powder material, such as nylon, polyamide, or metal alloys. Each material is chosen based on the specific requirements of the part, such as strength, flexibility, or heat resistance.

- 3D Model Preparation: A 3D model of the part is designed using CAD (Computer-Aided Design) software and then converted into a digital file compatible with the SLS printer. The model is sliced into thin layers, which guides the laser during the sintering process.

- Layer-by-Layer Printing: The printer begins by spreading a thin layer of the selected powder material onto the build platform. A high-powered laser then scans the surface, selectively fusing the powder particles in the areas defined by the digital model. This layer of fused material is then lowered, and another layer of powder is applied. The process repeats until the part is fully formed.

- Cooling and Solidification: After the part is printed, it is allowed to cool and solidify within the powder bed. This cooling process ensures that the material maintains its integrity and strength before it is removed from the build platform.

- Post-Processing: After printing, the part is carefully removed from the powder bed. Depending on the material and requirements, additional post-processing may be required, such as cleaning excess powder, polishing, or painting to enhance the part’s finish.

Reasons to Use Our Selective Laser Sintering (SLS)

Selective Laser Sintering offers numerous benefits over other 3D printing technologies, making it a preferred choice for manufacturing complex parts. Here are some of the key advantages:

- High Strength and Durability: SLS parts are known for their excellent mechanical properties, including strength, durability, and heat resistance. This makes them suitable for functional prototypes, end-use parts, and components exposed to harsh environments.

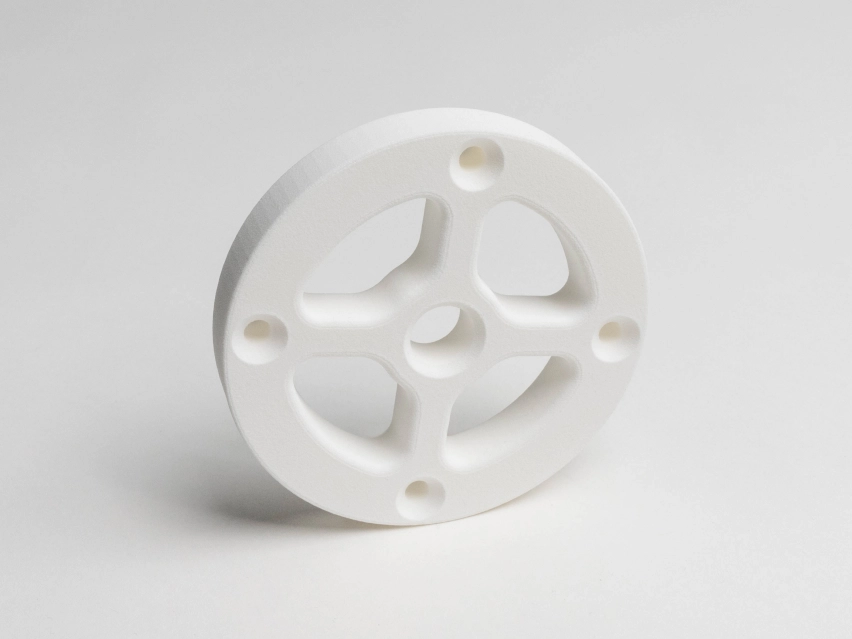

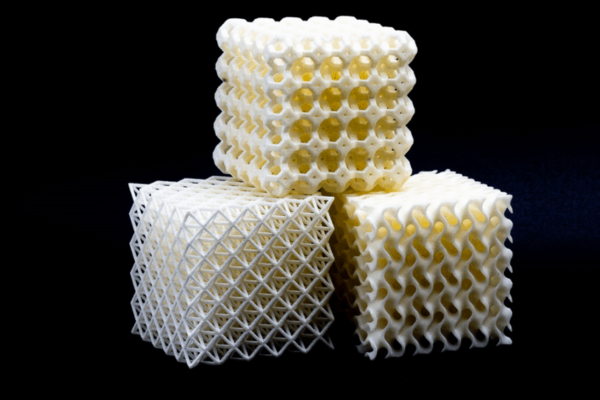

- Complex Geometries: SLS allows for the production of highly complex and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This is ideal for creating parts with detailed features, internal structures, or organic shapes.

- No Need for Support Structures: Unlike other 3D printing technologies, SLS does not require additional support structures to hold the part in place during printing. The surrounding powder acts as a natural support, reducing material waste and simplifying the post-processing step.

- Rapid Prototyping and Production: SLS is ideal for rapid prototyping, as it enables quick turnaround times and allows for iterative testing of designs. The technology is also capable of producing small to medium production runs efficiently and cost-effectively.

The SLS Advantage for Prototyping and Production

One of the key benefits of SLS is its suitability for both prototyping and end-use production. As a result, businesses can use SLS for every stage of product development, from design validation to low-volume production. The speed and accuracy of SLS enable designers to iterate on designs quickly, making it a cost-effective solution for prototyping before moving to full-scale production.

Additionally, SLS is ideal for producing small to medium batches of custom parts without the need for expensive molds or tooling. This allows companies to manufacture high-quality components at a lower cost, especially for products that require frequent design updates or unique features.

Start Your SLS Project with XC Machining

If you’re looking for high-performance, precise, and custom solutions, XC Machining offers Selective Laser Sintering (SLS) services that can bring your ideas to life. Whether you need prototypes, custom parts, or small production runs, our expert team and cutting-edge technology ensure that your project is executed with the utmost quality and efficiency.

Contact Us Today to discuss how our SLS services can meet your needs. Let us help you create innovative, high-performance parts with the precision and speed that only SLS can offer.